Torque Specs and Tips for 4D34 Gasket Kit Installation

- Torque Specs and Tips for 4D34 Overhaul Engine Gasket Kit Installation

- Why correct torque matters for an Overhaul Engine Gasket Kit

- Tools and supplies for 4D34 Overhaul Engine Gasket Kit installation

- Preparation steps before applying the Overhaul Engine Gasket Kit

- General torque strategy for the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck

- Step-by-step cylinder head bolt sequence for the 4D34 Overhaul Engine Gasket Kit

- Typical torque specifications for 4D34 Overhaul Engine Gasket Kit components (reference ranges)

- Practical head-bolt torque tips for success with your Overhaul Engine Gasket Kit

- Gasket handling and sealing techniques for the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck

- Common mistakes when using an Overhaul Engine Gasket Kit and how to avoid them

- Re-torqueing, break-in and verifying seals after installing the Overhaul Engine Gasket Kit

- Troubleshooting common seal and torque issues with Overhaul Engine Gasket Kit installations

- Brand summary & advantages: WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck

- Quick checklist when installing the WTA Overhaul Engine Gasket Kit

- FAQs about the 4D34 Overhaul Engine Gasket Kit and torque procedures

- Contact and product action

- References and authoritative sources for Overhaul Engine Gasket Kit procedures

Torque Specs and Tips for 4D34 Overhaul Engine Gasket Kit Installation

Why correct torque matters for an Overhaul Engine Gasket Kit

When fitting an Overhaul Engine Gasket Kit such as the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck, correct torque and tightening sequence are critical. Head gaskets and other engine seals depend on even, predictable clamping force to seal combustion chambers, coolant passages, and oil galleries. Under-torquing can lead to leaks and gasket failure; over-torquing risks bolt stretch, warping, or thread damage. This section explains the engineering reason behind torque accuracy and sets the stage for practical steps below.

Tools and supplies for 4D34 Overhaul Engine Gasket Kit installation

Before starting the overhaul using an Overhaul Engine Gasket Kit, prepare proper tools: a calibrated torque wrench (click-type and an angle-torque adapter), a set of metric sockets, extension bars, a straightedge and feeler gauges for head/cylinder inspection, gasket scraper, solvent, new fasteners where required, anti-seize and thread locker as specified, and clean lint-free rags. Accurate tools reduce variability and protect components. If the kit includes new torque-to-yield (TTY) bolts, those must be replaced and tightened by angle procedure only.

Preparation steps before applying the Overhaul Engine Gasket Kit

Proper prep improves sealing success when using an Overhaul Engine Gasket Kit. Steps include: (1) Thoroughly clean mating surfaces to remove old gasket material and carbon; avoid gouging. (2) Inspect head and block flatness with a straightedge and feeler gauges—if out-of-spec, machine the head. (3) Check bolt holes for thread damage and clean with a thread chaser if necessary. (4) Confirm you have the complete WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck—including cylinder head gasket, intake/exhaust gaskets, seals, and any valve stem seals. (5) Read OEM service manual torque specs and procedures for the ME997275 application; this guide provides practical guidance and typical ranges but does not replace OEM documentation.

General torque strategy for the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck

Torque strategy for an Overhaul Engine Gasket Kit centers on controlled, incremental tightening with a verified pattern. For cylinder head fasteners, the most reliable methods are staged torque (progressive Nm) or torque-to-angle procedures where specified. The objective is to seat the gasket uniformly, then achieve final clamping without inducing uneven stress. Always follow the bolt manufacturer's and OEM's instructions—if the head uses torque-to-yield bolts, DO NOT reuse them and perform the angle steps exactly.

Step-by-step cylinder head bolt sequence for the 4D34 Overhaul Engine Gasket Kit

Following an appropriate tightening sequence is as important as final torque values when installing an Overhaul Engine Gasket Kit. For inline-four engines like the 4D34 family, the typical pattern begins from the center and works alternately outward to minimize distortion. Use the following general sequence guidance (illustration recommended in workshop manual):

- Clean and lightly oil bolt threads if OEM allows; no oil if specified dry.

- Stage 1: Tighten all bolts to a low initial torque (e.g., 30–40 Nm) in sequence.

- Stage 2: Tighten all bolts to a medium torque (e.g., 70–90 Nm) in sequence.

- Final Stage: If OEM specifies torque-only, bring to final Nm (see table). If angle method specified, apply final torque then angle turns (e.g., 90° + 90°). Replace TTY bolts as required.

Note: These staged values are typical guidance. Always confirm exact numeric values and whether angle-turn steps are required for the ME997275 application in the OEM service manual. The table below summarizes typical torque ranges for common items on a 4D34 overhaul—treat them as reference starting points.

Typical torque specifications for 4D34 Overhaul Engine Gasket Kit components (reference ranges)

Use the following table as a practical reference while you confirm OEM values. These ranges reflect common workshop practice for similar Mitsubishi 4D3x-series engines; verify before final use.

| Component (Overhaul Engine Gasket Kit items) | Typical Torque / Method | Notes |

|---|---|---|

| Cylinder head bolts | Stage 1: 30–40 Nm; Stage 2: 70–90 Nm; Final: torque-to-angle (e.g., 90° + 90°) or final 100–140 Nm | Verify if TTY bolts used. Replace TTY bolts. |

| Head cover (valve cover) | 8–12 Nm | Hand-tight + small torque to compress gasket evenly. |

| Intake manifold bolts | 20–30 Nm | Do not over-torque plastic components. |

| Exhaust manifold nuts/bolts | 30–50 Nm | Hot-section fasteners often tightened to higher torque; use new studs/nuts if corroded. |

| Water pump & thermostat housing | 15–30 Nm | Follow gasket or O-ring seating guidance. |

| Main cap bolts (if removed) | 70–110 Nm (or OEM spec) | Critical for bearing callout—follow crank rebuild spec. |

| Connecting rod bolts (if replacing) | 50–90 Nm or torque-to-angle per OEM | Replace stretch bolts as recommended. |

Practical head-bolt torque tips for success with your Overhaul Engine Gasket Kit

1) Use a calibrated torque wrench and verify calibration annually. 2) Always torque bolts in the specified sequence to avoid head warp. 3) If bolts are torque-to-yield, use new bolts and perform angle-only steps as indicated. 4) Use small increments and allow metal relaxation between stages—wait a few minutes between stages if the engine was recently heated. 5) Mark bolts in the order you torque them to avoid mistakes. 6) If lubrication of threads is permitted by OEM, use the specified lubricant; lubrication can change clamp force significantly so never improvise.

Gasket handling and sealing techniques for the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck

Gasket handling is often overlooked but critical. The WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck includes precision-cut gaskets—keep them flat, clean and oil-free until installation. Do not bend or pre-seat gaskets on hot surfaces. Use only the sealants recommended by the gasket or engine manufacturer. For example, use a thin bead of gasket sealant on water jacket openings if OEM recommends it, but do not smear sealant under the head gasket unless explicitly specified.

Common mistakes when using an Overhaul Engine Gasket Kit and how to avoid them

Errors that lead to rework include reusing head bolts that are torque-to-yield, failing to clean mating surfaces, ignoring torque sequence, using incorrect thread lubrication, and not checking head/block flatness. Avoid these by following OEM instructions, using new fasteners where called for, and performing methodical staged tightening. If in doubt, consult a specialist or authorized service center for ME997275 Mitsubishi Truck engines.

Re-torqueing, break-in and verifying seals after installing the Overhaul Engine Gasket Kit

Some manufacturers recommend a re-torque after a set number of heat cycles; others prohibit re-torquing torque-to-yield bolts. For the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck, follow OEM guidance: if re-torque is allowed, perform it cold and using the same sequence. After assembly, run the engine to operating temperature, check for leaks, and allow a gentle break-in—avoid heavy load for the first few hours. After 50–100 km or the manufacturer-specified interval, re-inspect for leaks and check bolt torque only if permitted by OEM.

Troubleshooting common seal and torque issues with Overhaul Engine Gasket Kit installations

If you experience coolant loss, white smoke, oil contamination, or compression loss after installing an Overhaul Engine Gasket Kit, diagnose systematically: perform a compression test and a leak-down test to isolate the combustion seal. Inspect oil and coolant for cross-contamination. If you find gasket blow-by, re-check bolt torque sequence, flatness of head/block, and condition of threads/bolts. Often, premature gasket failure is traced to an uneven head surface or improper bolt replacement.

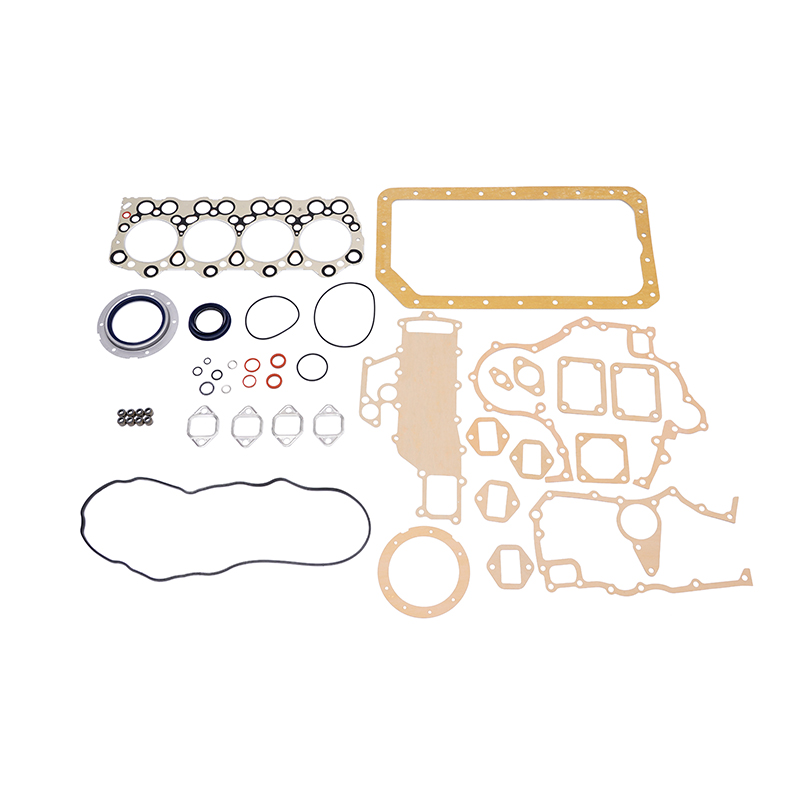

Brand summary & advantages: WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck

The WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck offers a complete repair solution designed for comprehensive engine maintenance. Advantages include: full set coverage (head gasket set plus all required seals), engineered fit for ME997275 applications to reduce fitment issues, and materials selected for durability under diesel combustion conditions. Using a complete overhaul gasket kit simplifies parts procurement and helps ensure that all sealing interfaces are addressed in one service window—minimizing repeat teardown risk.

Quick checklist when installing the WTA Overhaul Engine Gasket Kit

1) Confirm kit contains cylinder head gasket, intake/exhaust gaskets, valve cover gasket, seals, and any small gaskets. 2) Verify torque specs and TTY indications in OEM manual for ME997275. 3) Replace bolts designated as single-use. 4) Clean and measure mating surfaces. 5) Use staged torque sequence and observe angles where specified. 6) Record torque values and date of service for future maintenance.

FAQs about the 4D34 Overhaul Engine Gasket Kit and torque procedures

Q1: Is it necessary to replace cylinder head bolts when using the WTA 4D34 Overhaul Engine Gasket Kit?

A: If the OEM specifies torque-to-yield (TTY) bolts for the 4D34 head, you must replace them. Even if not TTY, many technicians prefer new head bolts if they show stretch or wear.

Q2: Can I use the torque values in this article without checking the OEM manual?

A: No. The values here are typical reference ranges. Always verify exact torque and angle procedures in the ME997275 Mitsubishi Truck service manual before final torque.

Q3: How important is the torque sequence?

A: Extremely important. The correct sequence minimizes distortion and prevents leaks. Always follow the specified center-out sequence for inline four heads like the 4D34.

Q4: What if the head is not flat after inspection?

A: If the head or block surface is out of OEM flatness tolerance, machining or resurfacing by a qualified shop is required before installing a new Overhaul Engine Gasket Kit.

Q5: When should I retorque after installation?

A: Only retorque if the OEM specifically permits it. For TTY bolts, re-torque is not permitted—replace bolts instead. For non-TTY designs, the OEM may specify a retorque interval or advice not to retorque.

Contact and product action

For genuine parts, torque information, and technical support for the WTA 4D34 Overhaul Engine Gasket Kit for ME997275 Mitsubishi Truck, contact our sales and technical team. View the product page or request the OEM torque data and installation checklist to ensure a proper overhaul. Contact us now to order or get support for your Overhaul Engine Gasket Kit installation.

References and authoritative sources for Overhaul Engine Gasket Kit procedures

Always consult these resources along with the vehicle's service manual for the most accurate, model-specific information:

- Head Gasket — Wikipedia: https://en.wikipedia.org/wiki/Head_gasket

- Torque Wrench — Wikipedia: https://en.wikipedia.org/wiki/Torque_wrench

- Bolt (fastener) — Wikipedia: https://en.wikipedia.org/wiki/Bolt_(fastener)

- Mitsubishi Motors official site: https://www.mitsubishi-motors.com

- Mitsubishi Fuso (commercial vehicle info): https://www.mitsubishi-fuso.com

- SAE International (technical papers on engine assembly practices): https://www.sae.org

Note: This article is intended to provide authoritative, practical guidance based on industry best practices for Overhaul Engine Gasket Kit installation. It does not replace the ME997275 Mitsubishi Truck OEM service manual. For model-specific torque figures and sequences, consult the official service documentation or authorized dealer.

Common Causes of Cylinder Head Gasket Failure on ISUZU 4JJ1

Rocker Cover Gasket vs Valve Cover Gasket: What’s the Real Difference?

Top 5 top gasket Company List and Products Compared

Engine Head Gasket 2026 Inspection Checklist Before Long Trips

OEM&ODM

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

What is your terms of payment?

T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit,

2. We respect every customer as our friend and we sincerely do business and make friends with them. no matter where they come from.

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

How about your delivery time?

Generally, it will take 5 to 7 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

High Quality Full Gasket Set 8ASX-10-271 WL Engine Overhaul Gasket Kits for Mazda B-SERIE 2.5

For ISUZU 6BG1 Truck Fit 1986-1992 F-Series FSR 500 FVR 12 JCS 420 1-87810609-0 Engine Head Gasket Kit Full Set 1878106090

OEM 5-87815243-0 Cylinder Head Gasket ISUZU 4JJ1 4JJ1-TC 4JJ1-TCX 4JK1-TC 4JK1-TCX

Scan QR Code

Scan QR Code

Tik Tok

YouTube

Facebook

LinkedIn

Scan QR Code

Whatsapp: +8618922275934

Whatsapp: +8618922276204

Whatsapp: +8618922271543