How to manufacturing engine cylinder head gasket

- How to Manufacture Engine Cylinder Head Gaskets: A Comprehensive Guide by WTA

- Understanding the Importance of Engine Cylinder Head Gaskets

- Material Selection: The Foundation of Quality Engine Cylinder Head Gaskets

- Manufacturing Process: Precision and Quality Control at Every Stage

- 1. Design and Engineering:

- 2. Material Preparation:

- 3. Die Cutting and Punching:

- 4. Surface Treatment (if applicable):

- 5. Quality Control:

- 6. Packaging and Distribution:

- Overhaul Repair Kits: A Comprehensive Solution for Engine Maintenance

- Engine Sealing Solutions for Various Makes and Models

- The Importance of Choosing a Reputable Engine Cylinder Head Gasket Supplier

- Frequently Asked Questions (FAQ)

- Conclusion: Partner with WTA Gasket for Superior Engine Sealing Solutions

How to Manufacture Engine Cylinder Head Gaskets: A Comprehensive Guide by WTA

Understanding the Importance of Engine Cylinder Head Gaskets

Engine cylinder head gaskets are critical components in any internal combustion engine. These seals prevent the leakage of combustion gases, coolant, and oil, ensuring efficient engine operation and preventing costly repairs. A faulty engine cylinder head gasket can lead to overheating, loss of power, and ly, engine failure. The manufacturing process of these gaskets is therefore extremely precise and demanding, requiring specialized equipment and expertise. Choosing a high-quality engine cylinder head gasket, like those produced by WTA Gasket, is crucial for ensuring engine longevity and performance.

Material Selection: The Foundation of Quality Engine Cylinder Head Gaskets

The choice of material significantly impacts the performance and durability of an engine cylinder head gasket. WTA Gasket utilizes a variety of materials, each chosen for its specific properties and suitability for different applications. Common materials include:

Compound Graphite Gaskets: Known for their excellent sealing capabilities, resistance to high temperatures and pressures, and flexibility. These are ideal for various engine types and applications.

Non-Compound Graphite Gaskets: Offer similar benefits to compound graphite gaskets but may be tailored for specific applications requiring enhanced properties.

Asbestos Gaskets: While less common due to health concerns, asbestos gaskets are still used in certain niche applications due to their exceptional heat resistance. WTA Gasket adheres to strict safety regulations in their handling and application.

Multilayer Steel Gaskets: These gaskets are particularly robust and suitable for high-performance engines, offering superior strength and resistance to extreme conditions.

The selection process considers factors like operating temperature, pressure, engine type, and the specific requirements of the customer. WTA Gasket works closely with clients to determine the optimal material for their needs.

Manufacturing Process: Precision and Quality Control at Every Stage

The manufacturing process of engine cylinder head gaskets involves several intricate steps:

1. Design and Engineering:

This initial phase involves meticulous design using CAD software to ensure the gasket perfectly matches the engine block and cylinder head. WTA Gasket’s experienced engineers leverage their expertise to optimize gasket design for maximum sealing efficiency and durability.

2. Material Preparation:

Once the material is selected, it undergoes careful preparation, including cutting, punching, and shaping to the precise dimensions specified in the design. This step requires highly accurate machinery and skilled operators.

3. Die Cutting and Punching:

High-precision die-cutting and punching machines are employed to create the intricate shapes and openings required in the gasket. This stage is critical for achieving the perfect fit and optimal sealing performance.

4. Surface Treatment (if applicable):

Depending on the chosen material and application, surface treatments such as coating or embossing may be applied to enhance gasket performance. These treatments can improve sealing, heat resistance, or corrosion protection.

5. Quality Control:

Rigorous quality control measures are implemented at every stage of the manufacturing process. WTA Gasket employs advanced testing equipment to ensure dimensional accuracy, material integrity, and overall gasket quality. This commitment to quality ensures that each gasket meets the highest industry standards.

6. Packaging and Distribution:

Finally, the completed gaskets are carefully packaged and prepared for distribution to customers worldwide. WTA Gasket prioritizes efficient and reliable logistics to ensure timely delivery.

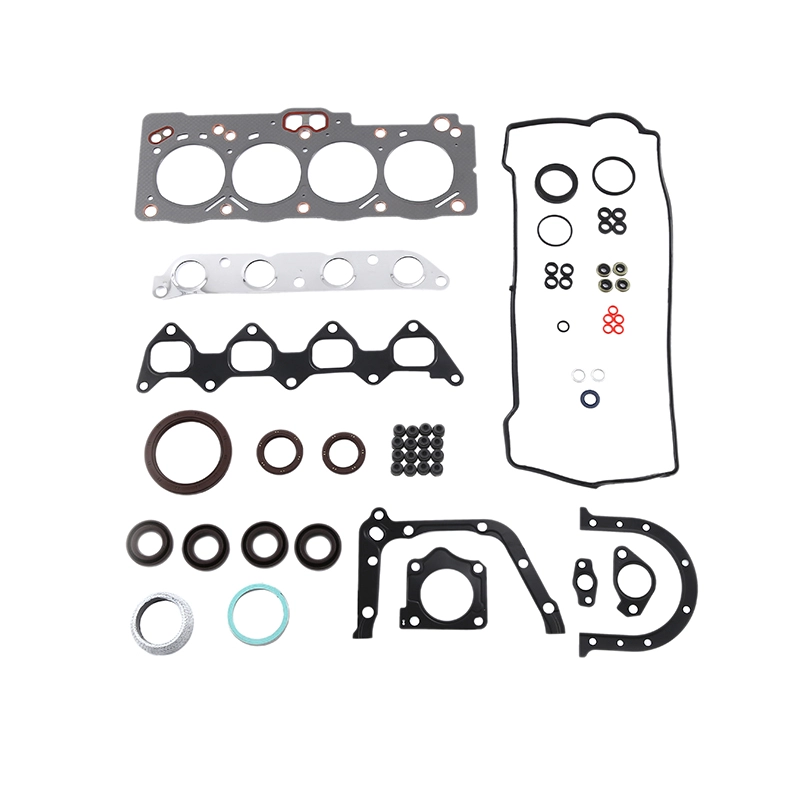

Overhaul Repair Kits: A Comprehensive Solution for Engine Maintenance

Beyond individual engine cylinder head gaskets, WTA Gasket also provides comprehensive overhaul repair kits. These kits typically include a complete set of gaskets and seals required for a major engine overhaul, providing customers with a convenient and cost-effective solution. This approach streamlines the repair process, saving time and resources for mechanics and workshops. The kits are specifically designed for various engine makes and models, ensuring a precise fit and optimal performance.

Engine Sealing Solutions for Various Makes and Models

WTA Gasket caters to a broad spectrum of automotive applications. Our expertise extends to producing high-quality engine seals and gaskets for a wide range of vehicles including:

Toyota

Nissan

Mitsubishi

Honda

Mazda

Isuzu

Kia

Daewoo

Volkswagen

Citroen

Ford

GM-Buick

Chery

Hino

BMW

Chevrolet

This extensive coverage ensures that WTA Gasket can provide solutions for diverse engine types and customer needs.

The Importance of Choosing a Reputable Engine Cylinder Head Gasket Supplier

Selecting a reliable supplier for your engine cylinder head gaskets is crucial for ensuring the longevity and performance of your engine. WTA Gasket's commitment to quality, precision, and customer satisfaction makes us a trusted partner for automotive manufacturers and repair shops worldwide. Our dedication to using superior materials and employing rigorous quality control measures ensures that our gaskets consistently meet the highest standards.

Frequently Asked Questions (FAQ)

Q: What materials do WTA Gaskets use?

A: We utilize a variety of materials including compound graphite, non-compound graphite, asbestos (where applicable and compliant with regulations), and multilayer steel gaskets, selected based on the specific application and customer requirements.

Q: What makes WTA Gaskets superior?

A: Our commitment to precision manufacturing, rigorous quality control, and the use of high-quality materials sets us apart. We prioritize cost-effectiveness without compromising on quality, exceeding customer expectations.

Q: Do you offer custom gasket manufacturing?

A: Yes, WTA Gasket offers custom design and manufacturing services to meet specific customer requirements and unique engine applications.

Q: What is your lead time for orders?

A: Lead times vary depending on order size and complexity. Please contact our sales team for a specific quote and lead time estimate.

Q: What is your warranty policy?

A: WTA Gasket provides a warranty on all our products. Details of the warranty policy are available upon request.

Q: How can I place an order?

A: You can place an order through our website, or by contacting our sales team directly via phone or email. We are happy to assist you with your order.

Q: Do you ship internationally?

A: Yes, WTA Gasket ships its products internationally. Please contact us for shipping information and costs.

Q: What types of gaskets do you produce?

A: We produce a wide variety of gaskets including cylinder head gaskets, valve cover gaskets, oil pan gaskets, intake/exhaust manifold gaskets, and other engine sealing components.

Conclusion: Partner with WTA Gasket for Superior Engine Sealing Solutions

Choosing the right engine cylinder head gasket is paramount for optimal engine performance and longevity. WTA Gasket, with its commitment to quality, precision, and customer satisfaction, offers a comprehensive range of high-quality engine sealing solutions. From material selection and manufacturing to rigorous quality control and timely delivery, we strive to exceed customer expectations. Contact us today to learn more about our products and services and discover how WTA Gasket can be your trusted partner for all your engine gasket needs. We are dedicated to providing cost-effective, high-performance engine seals and gaskets for a wide range of vehicle makes and models.

Wholesale toyota gasket kit manufacturer and supplier

Top 3rz engine gasket Manufacturers and Suppliers

Rocker Cover Gasket Material Types: Complete Guide for Selection and Performance

Where to Buy gaskets

OEM&ODM

How about your delivery time?

Generally, it will take 5 to 7 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

What is your terms of delivery?

EXW, FOB

What is your terms of payment?

T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

What is your terms of packing?

Generally, we pack our goods in WTA and SOYI packing. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

04111-16221Gasket Set AT170 AE91 AE100 5A-FE Engine Cylinder Head Gasket

High Quality Full Gasket Set 8ASX-10-271 WL Engine Overhaul Gasket Kits for Mazda B-SERIE 2.5

For ISUZU 6BG1 Truck Fit 1986-1992 F-Series FSR 500 FVR 12 JCS 420 1-87810609-0 Engine Head Gasket Kit Full Set 1878106090

Scan QR Code

Scan QR Code

Tik Tok

YouTube

Facebook

LinkedIn

Scan QR Code

Whatsapp: +8618922275934

Whatsapp: +8618922276204

Whatsapp: +8618922271543