The 10 Key Factors in engine gasket kit That Affect Cost

- Introduction: Why Understanding engine gasket kit Costs Matters

- 1. Material Selection and Raw Material Prices

- What to consider

- 2. Design Complexity and Engineering Requirements

- What to consider

- 3. Manufacturing Processes and Tooling

- What to consider

- 4. Tolerance and Quality Requirements

- What to consider

- 5. Testing, Validation and Certification

- What to consider

- 6. Kit Completeness and Contents

- What to consider

- 7. Production Volume and Economies of Scale

- What to consider

- 8. Surface Treatments, Coatings and Seals

- What to consider

- 9. Packaging, Traceability and Warranty

- What to consider

- 10. Logistics, Trade Costs and Market Segment

- What to consider

- Summary Table: 10 Factors and Their Impact on Cost

- How WTA Gasket Helps Control Cost While Ensuring Reliability

- Practical Buyer Checklist to Manage engine gasket kit Costs

- Conclusion

Introduction: Why Understanding engine gasket kit Costs Matters

When purchasing or producing an engine gasket kit, cost is rarely driven by a single element. Multiple technical, manufacturing, and commercial factors combine to determine final pricing. For fleet owners, repair shops, OEM purchasing teams, and aftermarket distributors, understanding these cost drivers enables smarter buying decisions, better negotiations, and more predictable maintenance budgeting. As specialists in automotive engine sealing, WTA Gasket offers insights into the 10 key factors that most significantly affect engine gasket kit cost, and how each factor can be managed without compromising reliability or performance.

1. Material Selection and Raw Material Prices

Material choice is fundamental. Common materials used in head gaskets and repair kits include multilayer steel (MLS), composite graphite, copper, asbestos-free fibers, and elastomeric seals. Each material has a distinct cost profile: MLS and copper are generally more expensive than composite or fiber-based gaskets due to higher material costs and more demanding manufacturing processes. Raw material price volatility (steel, copper, graphite) also directly impacts kit cost. For example, increases in global steel prices raise the base cost for MLS gaskets and stamped metal components.

What to consider

- Match material to engine requirements and durability expectations.

- Consider long-term total cost of ownership: cheaper materials may reduce initial cost but increase failure risk.

2. Design Complexity and Engineering Requirements

Complex engine geometries, integrated coolant/oil passages, variable valve timing systems, and turbocharger interfaces all require more intricate gasket designs. Higher complexity often means tighter tolerances, additional sealing layers, embossed or beaded sealing features, and custom cutouts — all of which increase engineering time, tooling complexity, and production cost. Custom designs also require more prototypes and validation cycles.

What to consider

- Standardized designs lower cost; bespoke designs raise it.

- Early design-for-manufacture input can reduce expensive iterations.

3. Manufacturing Processes and Tooling

Tooling and process choice strongly influence per-unit cost. Stamping, laser cutting, chemical etching, embossing, coining, and bonding are common processes. High-precision processes and specialized tooling (dies, presses, fixtures) have high capital expense but lower variable cost at high volumes. For low-volume or niche parts, tooling amortization raises unit cost.

What to consider

- High initial tooling costs justify themselves at scale; low volumes favor flexible processes.

- Investing in modern presses and automation improves consistency and can reduce long-run costs.

4. Tolerance and Quality Requirements

Engine gaskets are safety-critical. Tolerance tightness, surface finish, and dimensional accuracy affect sealing performance. Higher quality requirements demand stricter inspection, more scrap control, and advanced metrology, all of which increase costs. Certifications, end-user expectations, and warranty commitments also push manufacturers to invest in quality systems like ISO/TS or IATF standards.

What to consider

- Higher quality reduces field failures and warranty claims — a trade-off for higher upfront cost.

- Quality control processes should be aligned to the end market (OEM vs aftermarket).

5. Testing, Validation and Certification

Performance testing (leak tests, pressure cycling, thermal aging, and engine dynamometer validation) proves gasket reliability under simulated service conditions. OEMs typically require extensive validation and sign-off, which adds engineering hours, lab time, and possibly third-party testing. Certification for emission or safety-critical applications can further raise cost.

What to consider

- OEM-level validation is more costly than aftermarket bench testing but reduces field risk.

- Consider a risk-based test plan to balance cost and assurance.

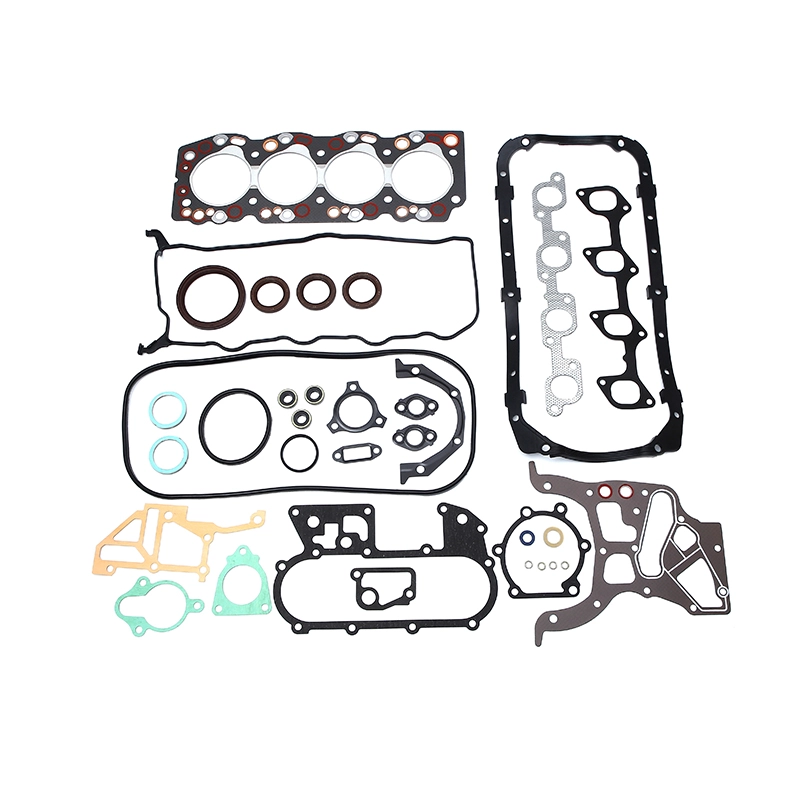

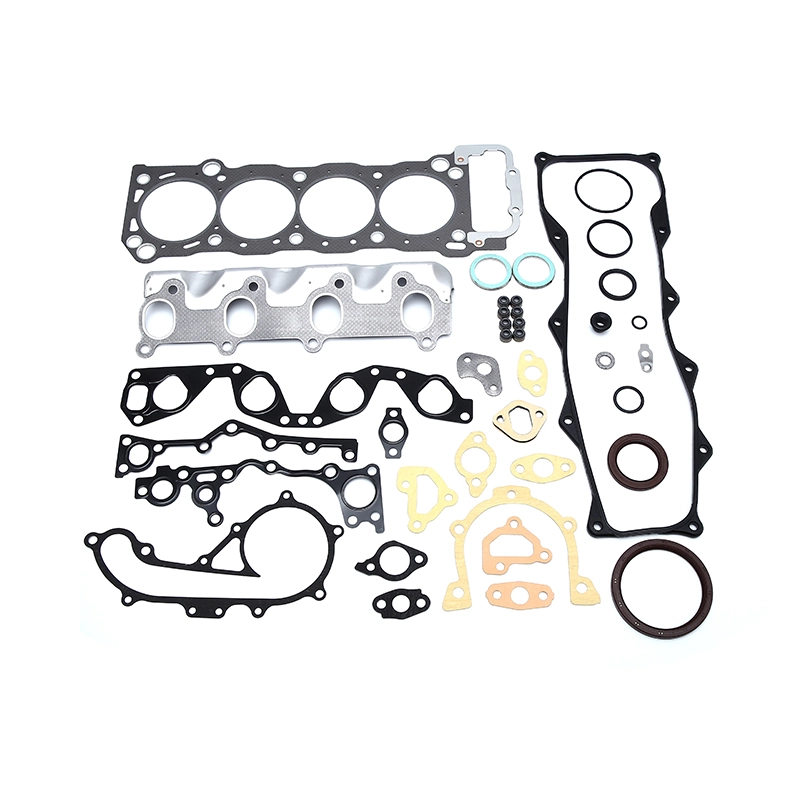

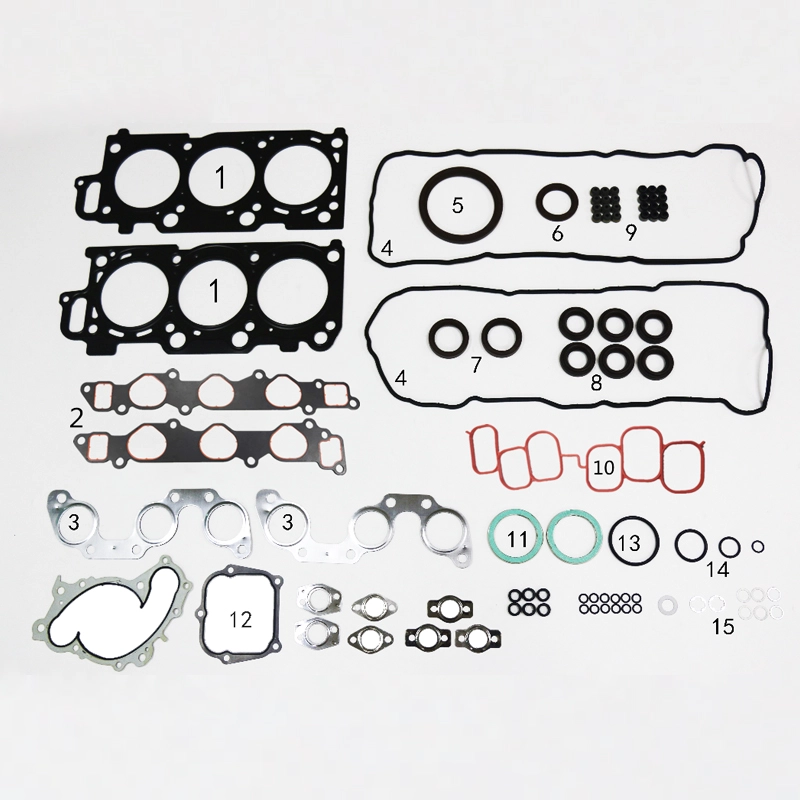

6. Kit Completeness and Contents

An engine gasket kit can be sold as a basic head gasket only, or as a full overhaul kit including valve cover gaskets, intake/exhaust manifold gaskets, oil pan gaskets, seals, O-rings, and fasteners. Kits with more components deliver greater convenience and perceived value but naturally cost more. Decisions about kit contents affect inventory, packaging size, and shipping costs.

What to consider

- Determine the customer need: do technicians prefer full kits to reduce procurement steps?

- Offering tiered kits (basic, expanded, High Quality) helps meet different price points.

7. Production Volume and Economies of Scale

Volume is one of the most powerful cost drivers. High-volume runs dilute fixed costs (tooling, setup, engineering) across more units, reducing per-kit costs. Low-volume or specialty parts lack those economies and will cost more per unit. Manufacturers like WTA Gasket optimize production planning to leverage batch sizes and minimize changeover costs.

What to consider

- Forecast demand accurately to optimize batch sizes and avoid overruns or stockouts.

- Consolidated orders and long-term contracts can secure better pricing.

8. Surface Treatments, Coatings and Seals

Additional processes including anti-corrosion coatings, graphite coatings, silicone beads, or specialized sealants add to material and processing costs. Treatments improve sealing under extreme conditions, compatibility with engine fluids, and longevity. Some engines require special coatings to meet friction or thermal transfer specifications, increasing complexity and cost.

What to consider

- Only specify special coatings if the application requires them; unnecessary coatings increase cost.

- Choose suppliers with validated application processes to avoid rework.

9. Packaging, Traceability and Warranty

Professional packaging protects parts during transit and improves brand perception. Traceability systems (batch codes, barcodes, QR codes) facilitate recalls and quality investigations but add printing and administrative cost. Warranty terms directly impact price: longer warranties imply higher perceived quality and potentially higher pricing to cover risk.

What to consider

- Invest in pragmatic traceability for high-value or critical parts.

- Packaging choices should balance protection, branding, and shipping weight.

10. Logistics, Trade Costs and Market Segment

Freight, duties, import/export compliance, and distribution margins are significant contributors to final cost. Selling into OEM channels often involves different pricing structures compared with aftermarket retail. Regional labor costs and local regulations also shape manufacturing location decisions and therefore cost. Additionally, brand positioning (High Quality OEM brand vs budget aftermarket) affects price points and required margins.

What to consider

- Localizing production can reduce lead times and tariffs but may increase labor costs.

- Evaluate total landed cost, not just factory price, when sourcing kits.

Summary Table: 10 Factors and Their Impact on Cost

| Factor | How it Affects Cost | Mitigation/Buyer Tip |

|---|---|---|

| Material | Major; High Quality materials cost more | Match material to application; avoid over-specifying |

| Design Complexity | Increases engineering and tooling cost | Standardize designs where possible; DFM early |

| Tooling & Manufacturing | High initial cost; lower per-unit at scale | Plan volumes; use modular tooling |

| Quality & Tolerances | Higher inspection and scrap costs | Align QC level with end-market risk |

| Testing & Certification | Adds lab and validation expenses | Adopt risk-based testing to control cost |

| Kit Contents | More parts = higher kit price | Offer tiered kit options |

| Volume | Higher volumes lower unit cost | Negotiate long-term purchase agreements |

| Coatings & Treatments | Additional process and material costs | Specify only necessary treatments |

| Packaging & Traceability | Adds printing and administration cost | Balance traceability needs with cost |

| Logistics & Market | Freight, duties, and margins affect landed cost | Calculate total landed cost and optimize supply chain |

How WTA Gasket Helps Control Cost While Ensuring Reliability

At WTA Gasket, founded in 2012, we specialize in producing cylinder head gaskets, overhaul repair kits, and other precision engine sealing components. Our experience with materials such as compound and non-compound graphite, multilayer metal, and asbestos-free fiber, combined with in-house design and testing capabilities, allows us to optimize designs for both performance and cost. By offering flexible kit configurations and leveraging production planning, we help OEMs and aftermarket customers get the right balance of price and reliability. Our production range supports many vehicle brands and models, which helps spread tooling costs and support competitive pricing.

Practical Buyer Checklist to Manage engine gasket kit Costs

- Specify minimum required performance and avoid over-engineering.

- Request detailed BOM to understand where costs are allocated.

- Compare quotes including tooling amortization and lead times.

- Consider multiple kit options (basic to High Quality) to match customer needs.

- Ask about traceability, warranty policy, and failure rates to assess true value.

Conclusion

engine gasket kit cost is the result of technical choices, manufacturing realities, and commercial considerations. The 10 factors outlined here — from material and design to testing, kit completeness, and logistics — together determine the final price and long-term value. Buyers should focus on matching specification to need, understanding total landed cost, and partnering with experienced manufacturers like WTA Gasket who can design, test, and produce reliable sealing solutions while optimizing cost performance.

Frequently Asked Questions

Q: What is the most expensive component of an engine gasket kit?A: Typically the head gasket material and any specialized sealing components (MLS or copper head gaskets) are the most costly due to raw material and precision processing.

Q: Can cheaper materials still provide acceptable performance?A: Yes in some low-stress applications, but for modern high-compression, turbocharged engines, High Quality materials and precise manufacturing are recommended to avoid failures.

Q: How does volume affect pricing?A: Higher production volumes dilute fixed costs such as tooling, reducing per-unit price. Small batches or specials cost more per unit.

Q: Are aftermarket kits as good as OEM kits?A: It depends on the manufacturer. Quality varies; some aftermarket suppliers meet or exceed OEM specs while others prioritize lower cost. Check certifications, material specs, and warranty terms.

Q: What should I ask a supplier to understand cost drivers?A: Request material specs, process descriptions, tooling amortization details, testing/validation reports, and full kit BOM and packaging details.

WTA Best professional Head gasket manufacturers and supplier brands

The 10 Key Factors in diesel engine gasket set That Affect Cost

The B2B Buyer’s Guide to Gasket Kits

Top toyota rz gasket set Manufacturers and Suppliers

OEM&ODM

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

What is your terms of payment?

T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

How about your delivery time?

Generally, it will take 5 to 7 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit,

2. We respect every customer as our friend and we sincerely do business and make friends with them. no matter where they come from.

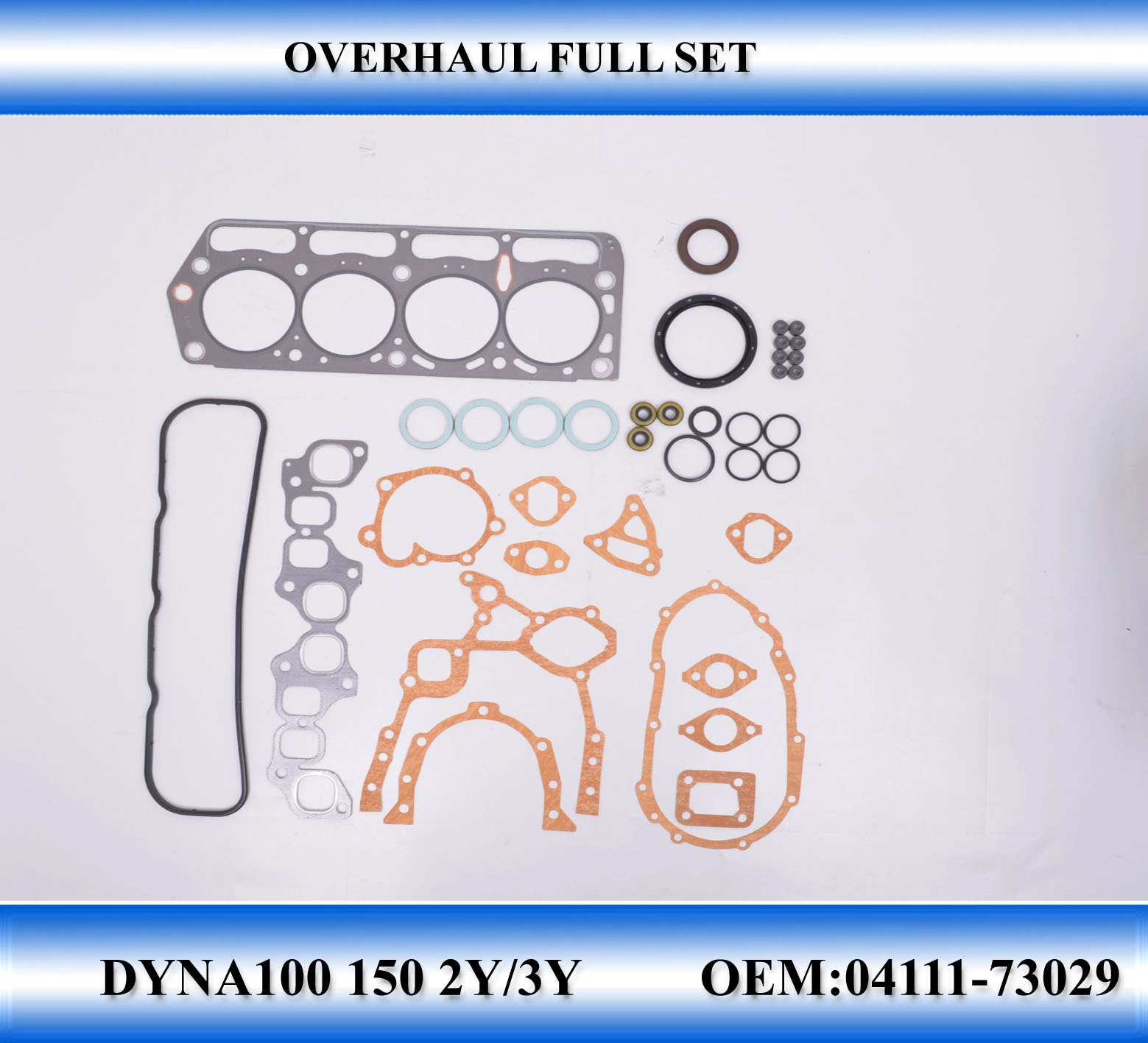

For Toyota Engine Gasket Kit 2Y 3Y HIACE III Bus (_H5/H6/H7/H8/H9/) 1.8 (YH50/YH60) OEM 04111-73029

04111-54050 FULL GASKET KIT TOYOTA 2L FOR HILUX LAND CRUISER & 4RUNNER 2.4 LTR

WTA 04111-54050 Full Gasket Kit is a complete engine gasket set designed for Toyota 2L 2.4 LTR engines, compatible with Hilux, Land Cruiser, and 4Runner models. Ensure optimal engine performance and leak prevention with this reliable Engine Full Gasket Kit.

For Toyota 2RZ Engine Overhaul Kit with OEM 04111-75032 Engine Head Gasket Repair Cylinder for 2RZ Engine

Scan QR Code

Scan QR Code

Tik Tok

YouTube

Facebook

LinkedIn

Scan QR Code

Whatsapp: +8618922275934

Whatsapp: +8618922276204

Whatsapp: +8618922271543