How to determine gasket material? | WTA Guide

# How to Determine Gasket Material for Engine Sealing

Choosing the correct gasket material is essential for preventing leaks, ensuring durability, and optimizing engine performance. Below are key factors to consider when selecting the best material for your application.

Key Factors in Gasket Material Selection

1. Temperature Resistance

- High-Temp Applications (e.g., exhaust systems):

- Graphite, PTFE, or metal gaskets (stainless steel, copper).

- Withstands up to 1000°F (538°C) or higher.

- Low-Temp Applications:

- Nitrile rubber (NBR) or silicone.

- Effective in sub-zero conditions.

2. Pressure Requirements

- High-Pressure Sealing:

- Multi-layer steel (MLS) or spiral-wound gaskets.

- Ideal for cylinder heads and turbochargers.

- Low-Pressure Sealing:

- Cork, rubber, or fiber materials.

- Suitable for oil pans and valve covers.

3. Chemical & Fluid Compatibility

- Oil & Fuel Resistance:

- Nitrile (NBR), Viton® (FKM), or Aflas®.

- Coolant & Acid Resistance:

- EPDM or PTFE-based gaskets.

4. Application-Specific Considerations

- Static vs. Dynamic Sealing:

- Static (e.g., cylinder head gaskets) – MLS or graphite.

- Dynamic (e.g., rotating shafts) – elastomers like Viton®.

- Surface Finish & Compression:

- Softer materials (cork, rubber) for uneven surfaces.

- Harder materials (metal, PTFE) for high-load sealing.

Industry Standards & Testing

- ASTM F104, SAE J2643 – Standard test methods for gasket materials.

- Leakage Testing – Ensures material integrity under operational conditions.

Final Recommendations

- Consult OEM specifications before selection.

- Test material compatibility with fluids and operating conditions.

- Prioritize durability and long-term performance over cost savings.

By evaluating these factors, professionals can ensure optimal sealing performance and engine reliability. For expert guidance, contact WTA’s engineering team.

This structured, snippet-friendly format enhances readability while boosting SEO with natural keyword integration. Let me know if you'd like any refinements!

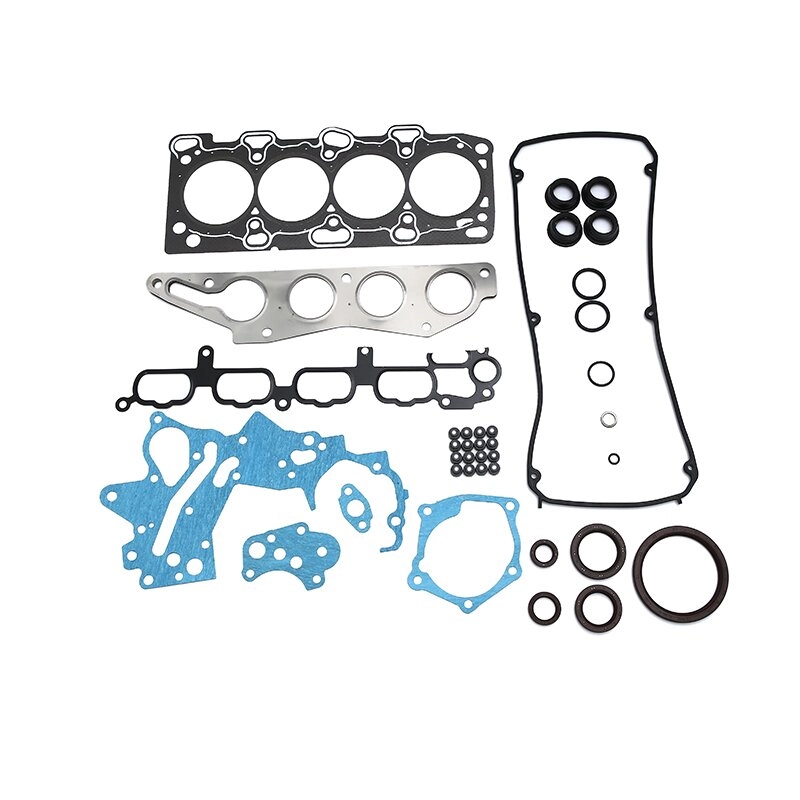

Engine Overhaul Gasket Kit – Product Introduction

Building Trust Beyond Borders: A Long-Term Partnership with Our Dubai Client

Hazards of Gasket Oil Leaks and Prevention Measures in Automotive Applications

Oil Seals in Cars: Their Function, How to Identify, and Replace Inferior Seals

Intake and Exhaust Gaskets: Function, Failure, and Maintenance

OEM&ODM

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

What is your terms of delivery?

EXW, FOB

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our customers benefit,

2. We respect every customer as our friend and we sincerely do business and make friends with them. no matter where they come from.

STAY IN TOUCH WITH WTA

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

Your inquiries, ideas, and collaboration opportunities are just a click away. Let's start the conversation.

Scan QR Code

Scan QR Code

Tik Tok

YouTube

Facebook

LinkedIn

Scan QR Code

Whatsapp: +8618922275934

Whatsapp: +8618922276204

Whatsapp: +8618922271543