Products

Discover our range of high-quality seals and gaskets designed to enhance your engine’s performance and reliability.

Explore our offerings to find precision-engineered components that ensure a perfect fit and superior durability for various engine applications.

Whether you need standard or custom solutions, our products are crafted to deliver exceptional quality and performance.

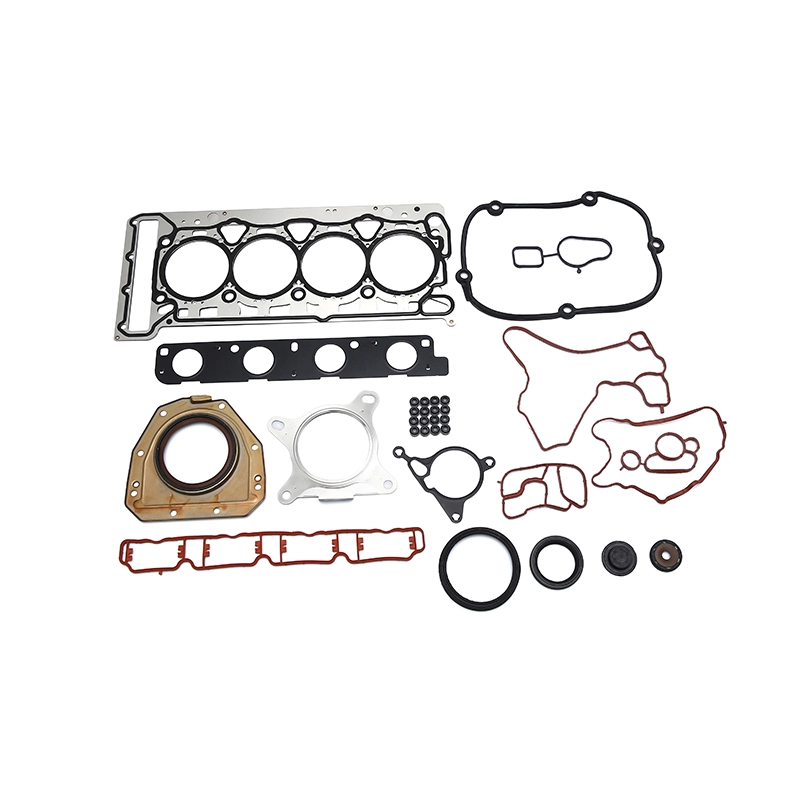

Overhual full gasket set Auto parts head gasket kit for VW Q5 2.0T OEM 06H 198 011 A

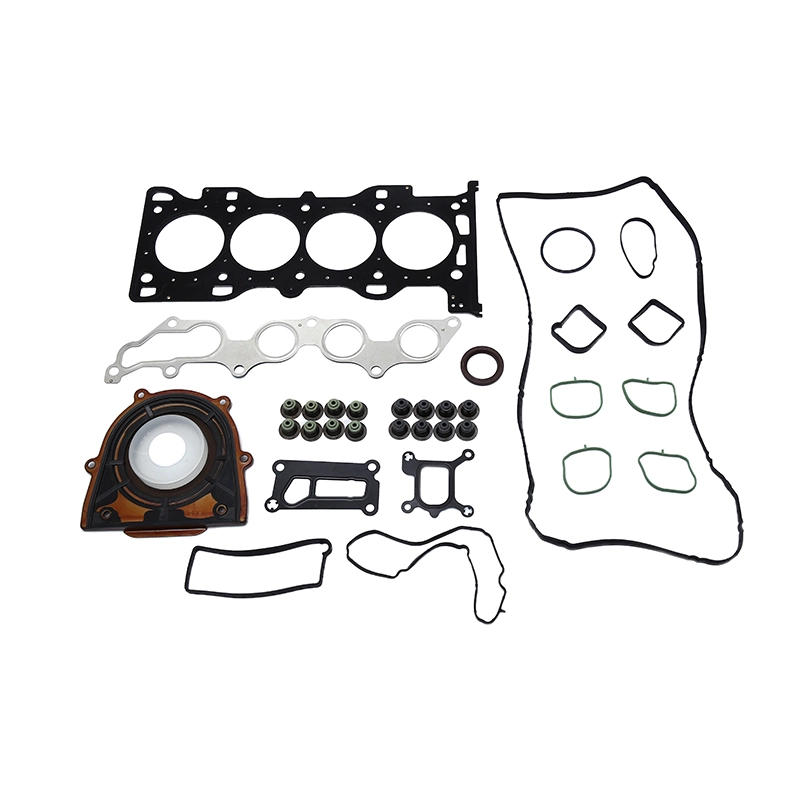

GASKET KIT-ENGINE REPAIR for Ford CARNIVAL 1.3 OEM 8LB3 10271 B

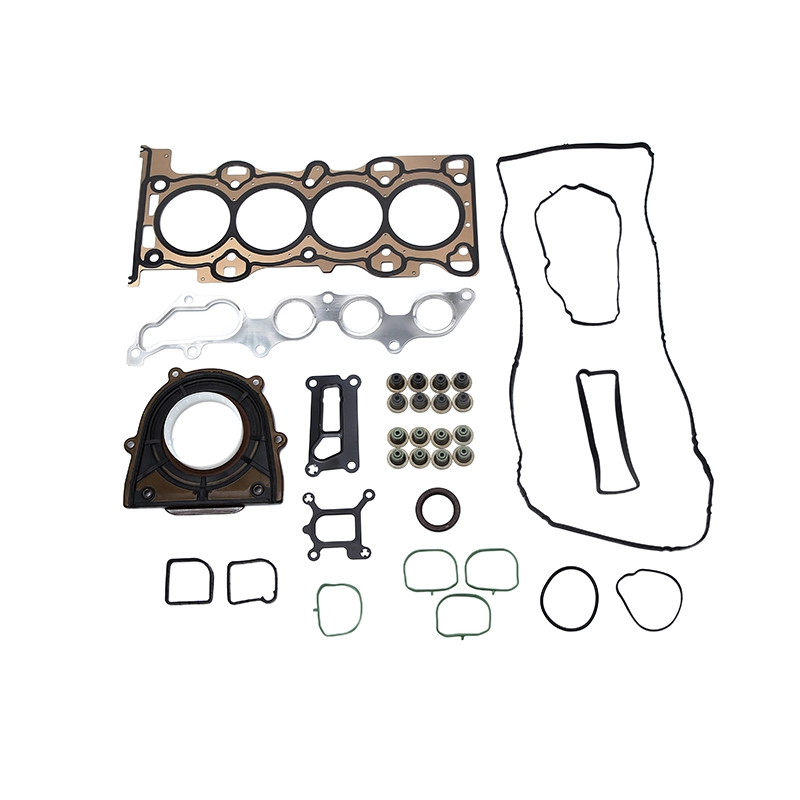

Overhover Gasket Kit Engine For FORD Carnival 1.6L 8V L4 3N21 6079 AA 3N216079AA 2001-2013

Auto Full Engine Gasket Set Fit 8G916013AA 8G91-6013-AA for FORD Mondeo IV 2.3 2007-2015

1S7G 6013 AA Full Gasket Kit for Ford 2.0t Gasket Kit - Ford Engine Gasket Kit, Overhaul Gasket Kit

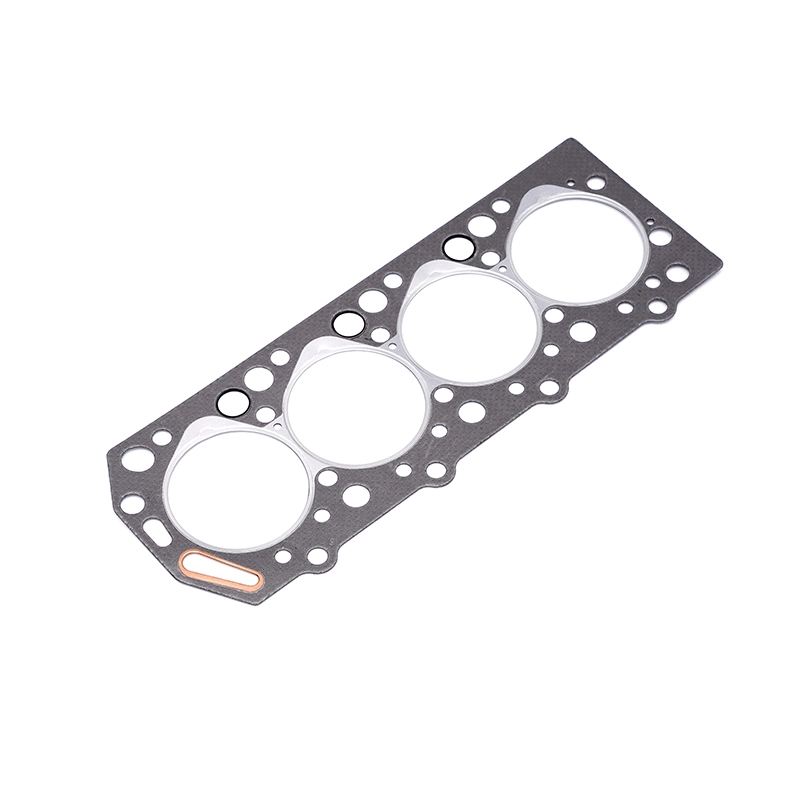

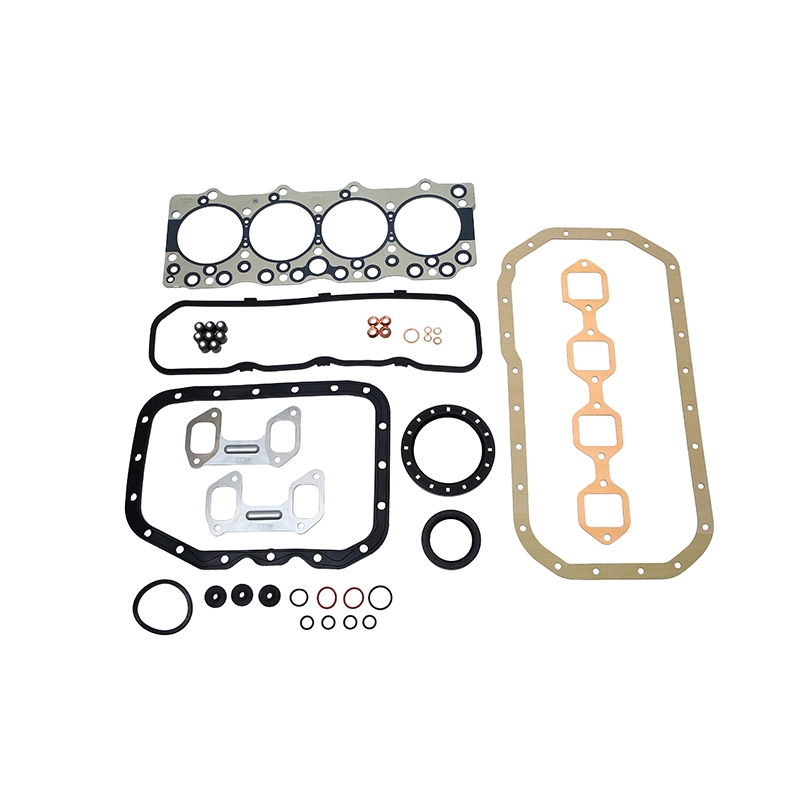

Head gasket top gasket Cylinder for Mitsubishi 4D56T L200 OEM ME204036

Cylinder head gasket top gasket for MITSUBISHI 4D56 OEM MD112531

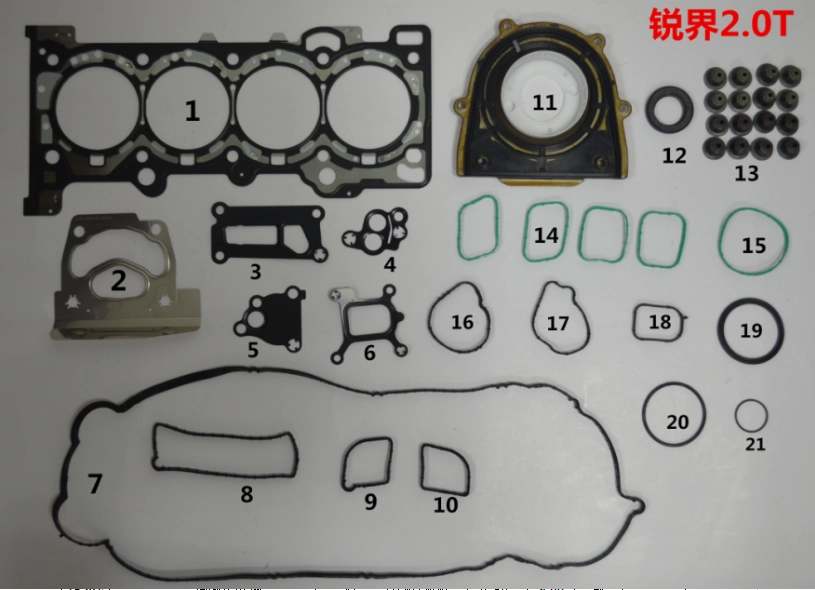

ENGINE MODEL EDGE 3.5 Auto Parts Overhaul Full Set Best Gasket for Ford OEM AT4Z-6079-A Manufacturers

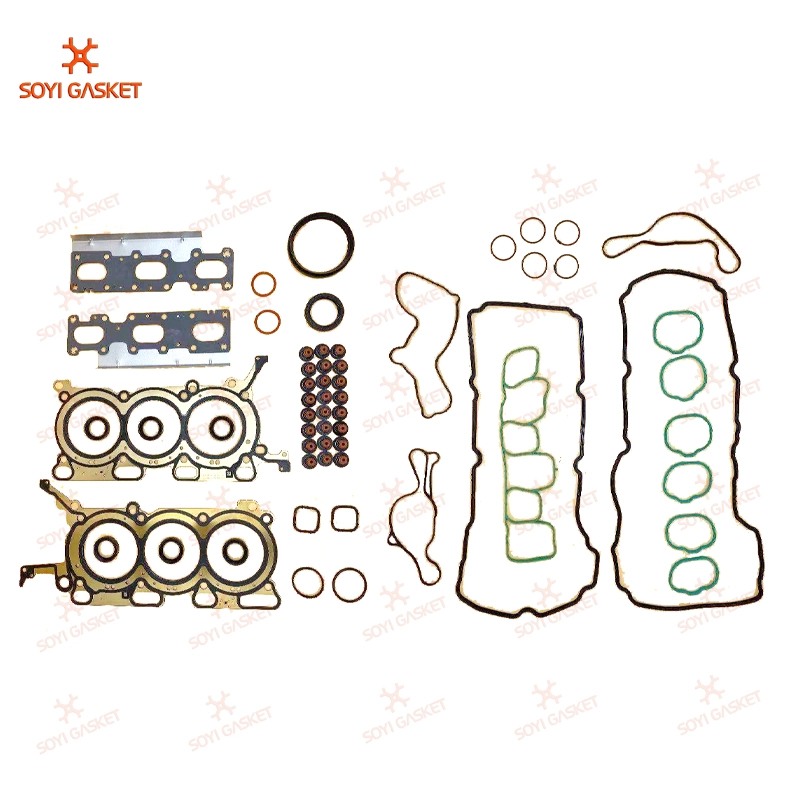

WTA High Quality Full Gasket Set EDGE 2.0T Engine For Ford FSGE-6079-AB

WTA High Quality Full Gasket Set EDGE 2.0T Engine for Ford FSGE-6079-AB. Complete Engine Overhaul Cylinder Head Gasket Kit. High Quality Overhaul Full Gasket Set and Engine Auto Parts Gasket Set for dependable sealing and extended engine life.

Engine Cylinder Head Gasket Kit 3S4G 6051 BG for Ford FOCUS 1.8

Engine Gasket Repair Kit for Ford FOCUS 1.6 - OEM BM51 6051 AB

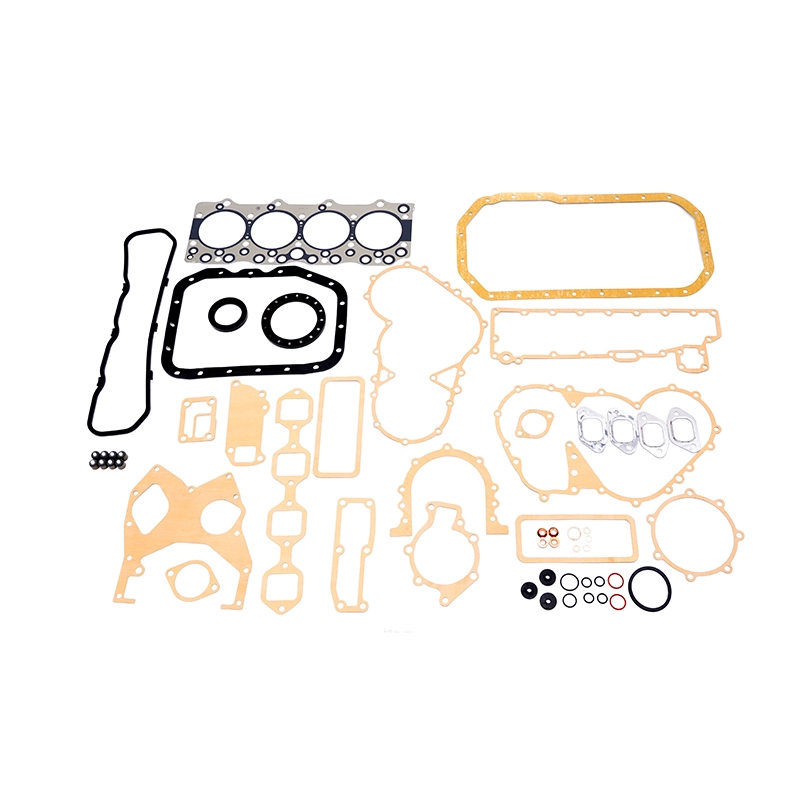

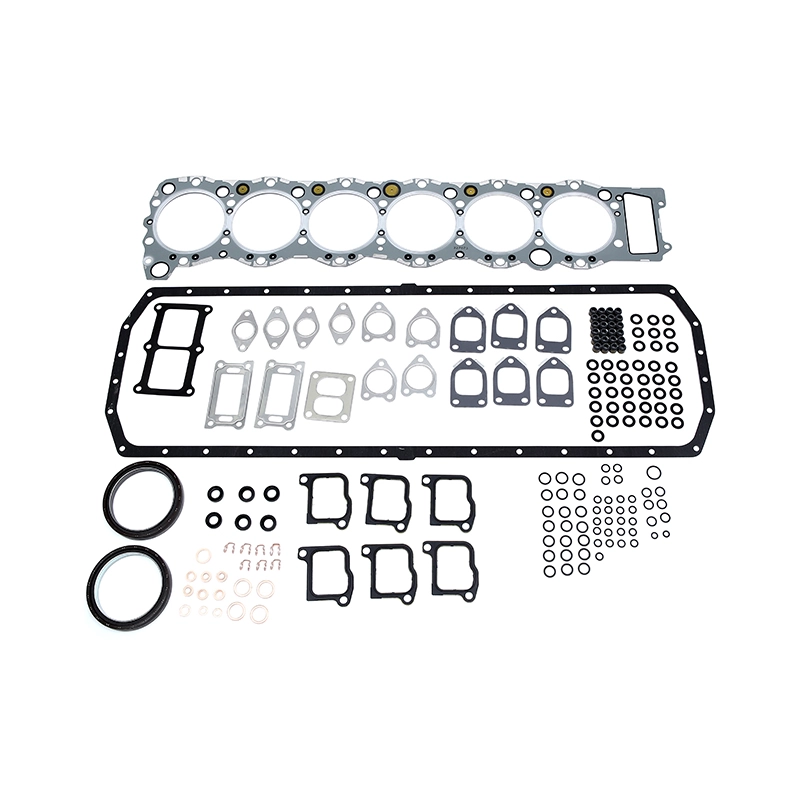

5-87810367-1 5878103671 Gasket Sets for Isuzu 4BE1 4BG1 Engine Reliable Overhaul Kits

5-87810462-0 5878104620 Engine Overhaul Gasket Set Compatible with Isuzu Engine 4BD2 4BD1 Compatible with Hitachi Excavator

6WG1 EFI Engine Overhaul Gasket Set for ISUZU Truck & Diesel OEM 1-87813916-0

6WG1 Engine Overhaul Gasket Set for ISUZU Truck & Diesel OEM 1-87815813-0

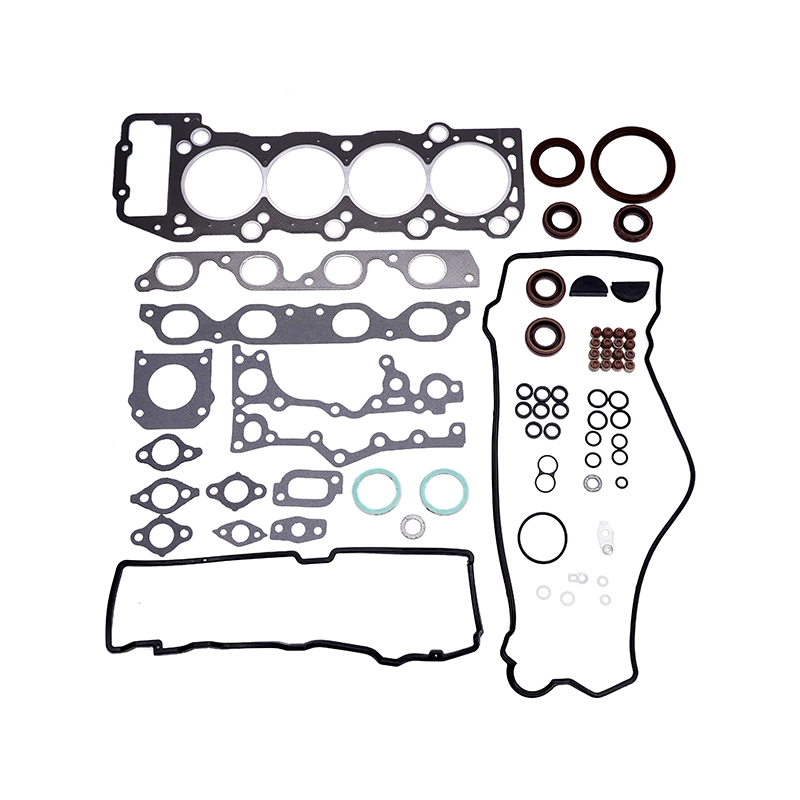

Engine Full Gasket Repair Kit for MITSUBISHI 4A91 OEM MW300358

Discover the WTA Engine Full Gasket Repair Kit for MITSUBISHI 4A91, OEM number MW300358. This high-quality engine full gasket ensures a perfect fit and reliable sealing performance for your 4A91 engine. Ideal choice for professional engine repairs.

4HG1 Complete Overhaul Full Gasket Set Repair Kits Cylinder Head Gasket 5-87813-352-0

WTA 4HG1 Complete Overhaul Full Gasket Set Repair Kits — Cylinder Head Gasket 5-87813-352-0. High Quality full gasket set for complete engine rebuilds. Precision cylinder head gasket set prevents leaks and restores performance. Buy now.

Isuzu Overhaul Full Complete Head Gasket Set For 4HG1 New Type 5-87813954-0

5-87811869-2 Engine Overhaul Gasket Set Suitable for ISUZU NPR66 4HF1 5878118690 - OEM PARTS FOR ISUZU

5-87811869-2 Engine Overhaul Gasket Set for ISUZU NPR66 4HF1 (5878118690) — WTA OEM parts for ISUZU. Complete engine gasket kit delivers precision fit, reliable sealing and long service life. Perfect replacement for 5-87811869-2 engine gasket needs.

Engine Gasket Repair Kit for ISUZU 4HF1 OEM 5-87814033-0 Engine Overhaul Full Set 5-87814033-0

Isuzu Truck Engine Parts 5-87812706-1 Engine Overhaul Gasket Kit 4JB1

2TZ-FE 2TZFE 2TZ Engine Overhaul Gasket Kit 04111-76070 04111-76071 Full Gasket Set Compatible for Toyota PREVIA 16V 2.4L

Engine Auto parts Overhaul full gasket set for VW C6 AUDI 3.0 OEM 06E 198 011 G

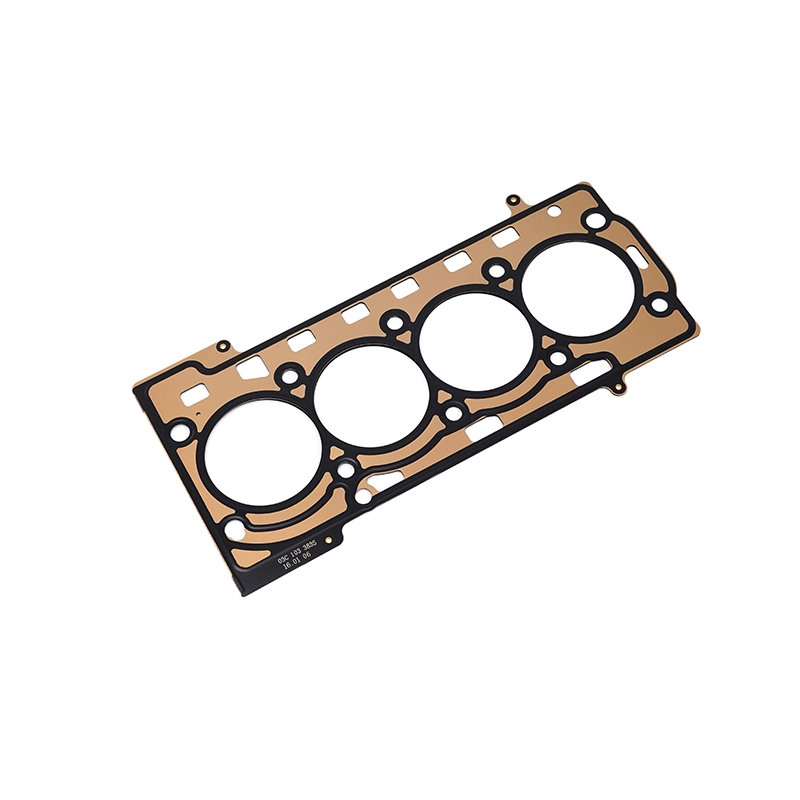

Head gasket top gasket for VW Magaotan 1.4T OEM 03C 103 383AA CN

Customized Engine Gasket Solutions: Comprehensive Optimization from Materials to Dimensions

In the intricate world of automotive and industrial engineering, where precision and performance converge, the role of seemingly small components often goes unnoticed until a failure occurs. Among these, engine gaskets stand as silent guardians, maintaining the integrity of fluid paths and combustion chambers under immense stress. While standard, off-the-shelf gaskets serve a vast majority of applications, there are critical instances where a generic solution simply won't suffice. This is where customized engine gasket solutions emerge as an indispensable offering, providing unparalleled optimization from the very selection of materials to the precise calibration of dimensions.

This deep dive explores the multifaceted world of custom gaskets, revealing why they are not just an alternative but often the only viable path to peak engine performance, reliability, and longevity, particularly for unique, high-performance, or legacy applications.

The Imperative for Customization: Beyond the Standard

Why would an engineer, mechanic, or enthusiast opt for a customized gasket when a seemingly endless array of standard products exists? The answer lies in the fundamental limitations of mass production when faced with unique challenges.

-

1. Unique Engine Designs and Prototypes: The automotive landscape is constantly evolving, with new engine architectures, experimental designs, and bespoke modifications emerging. For these one-off builds, concept vehicles, or niche production runs, standard gaskets simply don't fit the bill. Custom solutions provide the necessary sealing for non-standard bolt patterns, port shapes, or fluid passages.

-

2. Performance Upgrades and Extreme Conditions: Modifying an engine for increased power output, higher boost pressures, or more aggressive cam profiles drastically alters its operating environment. Standard gaskets, designed for factory specifications, may quickly succumb to the elevated temperatures, pressures, and dynamic forces. Custom gaskets, crafted from advanced materials and engineered for specific stress points, become critical to prevent premature failure and ensure optimal sealing under extreme conditions.

-

3. Obsolete or Discontinued Parts: Classic car restoration and the maintenance of older industrial machinery frequently encounter the challenge of discontinued parts. When original equipment (OE) gaskets are no longer manufactured, custom fabrication becomes the only way to preserve the authenticity and functionality of these cherished or vital machines.

-

4. Specific Environmental and Operating Conditions: Beyond typical engine environments, some applications face unique external factors. This could include engines operating in corrosive atmospheres, extremely humid conditions, or environments with specific chemical exposures. Custom material selection ensures the gasket's longevity and integrity against these external threats.

-

5. Optimizing Sealing Performance: Even if a standard gasket "fits," it might not provide the optimal sealing performance for a particular application. Custom solutions allow for fine-tuning of gasket thickness, compression characteristics, and surface coatings to achieve superior sealing, reduce blow-by, and improve efficiency.

-

6. Cost-Effectiveness for Small Batches: While seemingly counterintuitive, for low-volume production or single-unit requirements, custom gasket manufacturing can be more cost-effective than attempting to retrofit standard parts or waiting for a rare, discontinued component. It also eliminates the need for expensive tooling if flexible manufacturing methods like laser or waterjet cutting are employed.

In essence, customization is about achieving a perfect synergy between the gasket and its specific application, guaranteeing a level of performance and reliability that a generic solution simply cannot match.

Comprehensive Optimization: The Pillars of Custom Gasket Solutions

The true power of custom gasket solutions lies in the ability to precisely optimize every aspect of the gasket, from the fundamental materials it's made from to its exact physical dimensions. This comprehensive approach ensures peak performance and longevity.

1. Material Selection: The Foundation of Performance

The material chosen for a gasket is arguably the most critical decision in custom manufacturing. It dictates the gasket's ability to withstand temperature, pressure, chemical exposure, and mechanical stress. An experienced custom gasket provider offers a vast array of materials, each with unique properties.

A. Common Gasket Materials and Their Properties:

-

· Multi-Layer Steel (MLS):

-

· Composition: Typically consists of two to five layers of stainless steel or carbon steel, often with elastomer coatings (e.g., Viton, silicone) on the outer layers.

-

· Properties: Excellent temperature resistance (up to 1000°C+ for exhaust applications), high pressure resistance, superior durability, minimal creep, and good elasticity. The layers allow for differential expansion and provide robust sealing through controlled localized compression (e.g., via embossed beads).

-

· Applications: Modern cylinder head gaskets, exhaust manifold gaskets, turbocharger gaskets, high-performance engines, and applications demanding extreme heat and pressure.

-

-

· Graphite Gaskets:

-

· Composition: Made from highly compressible exfoliated graphite, often reinforced with a metallic core (e.g., stainless steel foil or mesh).

-

· Properties: Exceptional temperature resistance (up to 500-600°C for flexible graphite), excellent chemical resistance, high compressibility, and good thermal conductivity. Can conform well to irregular surfaces.

-

· Applications: Exhaust manifold gaskets (especially older designs), high-temperature industrial sealing, flanges, and some cylinder head applications.

-

-

· Composite Gaskets (Fiber/Rubber):

-

· Composition: Typically made from a blend of synthetic fibers (e.g., aramid, carbon, cellulose), inorganic fillers, and elastomeric binders (e.g., NBR, SBR).

-

· Properties: Good general-purpose sealing, moderate temperature and pressure resistance (up to 200-300°C), good conformability, and cost-effectiveness. Can be specifically engineered for oil or coolant resistance.

-

· Applications: Valve cover gaskets, oil pan gaskets, water pump gaskets, thermostat housing gaskets, and other non-combustion engine seals.

-

-

Cork Gaskets:

-

· Composition: Made from granulated cork mixed with a binder (e.g., rubber).

-

· Properties: Very high compressibility, excellent conformability to uneven surfaces, good for low-pressure applications, good vibration dampening.

-

· Applications: Older valve covers, oil pans, transmission pans, and applications where very low clamping forces are used. Limited temperature and pressure resistance.

-

-

· Rubber Gaskets (Elastomers):

-

· Composition: Various synthetic rubbers, each with specific properties.

-

· NBR (Nitrile Butadiene Rubber): Good oil, fuel, and abrasion resistance. Moderate temperature range (-40°C to 120°C).

-

· Silicone: Excellent high and low-temperature resistance (-60°C to 230°C+), good flexibility, excellent ozone and UV resistance. Poor fuel resistance.

-

· Viton (Fluorocarbon Rubber): Exceptional high-temperature resistance (up to 250°C+), excellent chemical resistance (fuels, oils, aggressive chemicals).

-

· EPDM (Ethylene Propylene Diene Monomer): Excellent weather, ozone, and steam resistance. Good for coolant applications. Poor oil resistance.

-

-

· Applications: O-rings, valve cover gaskets (silicone), thermostat seals (EPDM), oil cooler gaskets (Viton), and various fluid seals.

-

-

· Felt Gaskets:

-

· Composition: Compressed wool or synthetic fibers.

-

· Properties: Good for oil retention, dust sealing, and light pressure applications.

-

· Applications: Older spindle seals, dust seals, minor oil retention.

-

-

· Paper Gaskets:

-

· Composition: Cellulose fibers, often treated.

-

· Properties: Inexpensive, good for low-pressure, low-temperature, dry applications. Limited fluid resistance.

-

· Applications: Carburetor gaskets, very light-duty seals.

-

B. Matching Material to Application: A Critical Process

Customization begins with a thorough understanding of the operating environment:

-

· Temperature Range: What are the minimum and maximum temperatures the gasket will experience? (e.g., exhaust gaskets need much higher heat resistance than an oil pan gasket).

-

· Pressure Range: What are the peak pressures the gasket must seal against? (e.g., combustion pressures in a cylinder vs. atmospheric pressure in a valve cover).

-

· Chemical Compatibility: What fluids will the gasket be exposed to? (e.g., engine oil, coolant, gasoline, diesel, exhaust gases, brake fluid). Some materials degrade rapidly in contact with certain chemicals.

-

· Compressibility and Recovery: How much compression is available, and how well must the gasket rebound to maintain a seal during thermal cycling?

-

· Vibration and Dynamic Stress: Will the gasket be subjected to constant vibration or dynamic movements that could cause wear or fatigue?

-

· Surface Finish: The roughness of mating surfaces influences gasket material choice. Some materials conform better to imperfect surfaces than others.

-

· Clamping Load: The available bolt torque and material strength must be considered. Some materials require higher clamping loads to seal effectively, while others can be damaged by excessive force.

C. Advanced Coatings and Surface Treatments: Enhancing Performance

Beyond the base material, custom gasket solutions can incorporate specialized coatings to further optimize performance:

-

· Elastomer Coatings (e.g., Viton, Silicone): Applied to MLS gaskets to fill microscopic imperfections on mating surfaces, enhancing cold sealing and preventing fluid leaks.

-

· Graphite/PTFE Coatings: Can reduce friction during assembly, provide non-stick properties, and improve chemical resistance.

-

· Anti-Stick Coatings: Prevent the gasket from bonding to the mating surfaces, making future disassembly easier.

-

· Heat-Resistant Coatings: For extreme temperature applications, specialized ceramic or metallic coatings can extend lifespan.

2. Design & Dimensions Optimization: Precision Engineering

Once the ideal material is selected, the physical design and precise dimensions of the gasket are meticulously optimized. This goes far beyond simply tracing an old gasket.

A. Precision Manufacturing and CAD/CAM:

-

· Computer-Aided Design (CAD): Engineers use sophisticated CAD software to design gaskets with extreme precision. This allows for detailed modeling of bolt holes, fluid passages, port shapes, and sealing beads.

-

· Computer-Aided Manufacturing (CAM): CAM software translates the CAD designs directly into instructions for manufacturing machinery (e.g., laser cutters, waterjet cutters, CNC presses), ensuring exact replication of the design.

-

· Reverse Engineering: For obsolete parts, 3D scanning and sophisticated measurement tools can accurately capture the dimensions of an existing part, even if it's damaged, to create new CAD models.

B. Critical Design Considerations:

-

· Tolerance Stack-up: Gaskets must account for the cumulative variations in dimensions of mating engine components. Custom design ensures the gasket fits optimally within these tolerances, providing a reliable seal without being too loose or too tight.

-

· Compression Ratio (for Gasket Materials): The gasket must compress by a specific amount when installed to create an effective seal. Design ensures the correct thickness and material properties to achieve this "crush" without over-compressing (damaging the gasket) or under-compressing (causing leaks).

-

· Bead/Embossment Design (for MLS Gaskets): In MLS gaskets, precisely engineered raised beads or embossments around critical sealing areas (combustion chambers, fluid passages) are crucial. These beads deform under clamping load, creating high localized sealing pressures. Custom design allows for optimizing the shape, height, and location of these beads for specific engine pressures and surface finishes.

-

· Bolt Load Distribution: The design must consider how clamping force is distributed by the bolts across the gasket surface. Proper hole placement, reinforcement around bolt holes, and overall gasket shape ensure even pressure, preventing high-stress points or areas of insufficient sealing.

-

· Fluid Path Integration: The gasket's design must perfectly align with all fluid passages (oil, coolant, fuel, air) and combustion chambers. Any misalignment, even fractional, can lead to leaks or restricted flow.

-

· Surface Finish Requirements: Some gasket materials require specific surface finishes on the mating engine components for optimal sealing. Custom solutions can sometimes incorporate features or coatings that allow for sealing on less-than-perfect surfaces, though ideal surface finish is always recommended.

-

· Stress Relaxation and Creep: Over time, some gasket materials can "creep" or experience stress relaxation, losing some of their initial compression. Custom material selection and design can mitigate these effects, ensuring long-term sealing integrity.

-

· Thermal Cycling Accommodation: Engines experience significant temperature fluctuations. Gasket design must accommodate the differential thermal expansion and contraction of mating components, preventing "scrubbing" or loss of seal integrity during heating and cooling cycles.

3. Manufacturing Processes for Custom Gaskets: Precision at Every Step

The manufacturing process must be precise to translate the optimized design into a functional gasket. Custom gasket manufacturers utilize various advanced techniques.

-

· Die Cutting: A traditional method where a custom-made die (a sharp steel rule blade) is pressed into the gasket material to cut out the shape. Ideal for high-volume production once the die is made, but tooling costs can be high for one-off custom parts.

-

· Laser Cutting: Highly precise, computer-controlled lasers cut the gasket material. This method offers extreme accuracy, clean edges, and is excellent for complex shapes and prototyping, as it requires no physical tooling beyond the digital design.

-

· Waterjet Cutting: Uses a high-pressure stream of water (often mixed with abrasive particles) to cut through materials. Similar to laser cutting, it offers high precision for complex shapes and is suitable for materials that might be damaged by heat (e.g., some rubbers).

-

· Molding: For certain rubber or composite gaskets, compression molding or injection molding may be used, particularly for parts with complex 3D features or integrated seals (e.g., rubber overmolded onto a metal carrier).

-

· Prototyping and Testing: Before full production, prototypes are often created using flexible methods like laser or waterjet cutting. These prototypes can then be test-fitted and even subjected to functional testing (e.g., pressure testing, leak down testing) to validate the design and material choice in a real-world scenario.

-

· Quality Control (QC): Rigorous QC is paramount for custom gaskets. This includes dimensional checks, material verification (e.g., hardness testing, spectroscopy), visual inspection for defects, and batch traceability.

Applications and Case Studies (Illustrative Examples)

The need for customized gasket solutions spans a wide array of applications:

-

· Classic Car Restoration: Restoring a vintage engine to its original glory often means sourcing parts for models that stopped production decades ago. Custom gaskets ensure authenticity and performance where OE parts are unobtainable.

-

· High-Performance Racing Engines: Race engines operate at extreme temperatures, pressures, and RPMs. Standard gaskets simply won't hold up. Custom MLS gaskets, designed for specific bore sizes, compression ratios, and head materials, are crucial for sealing power.

-

· Industrial Power Units: Large industrial engines (e.g., in power generators, marine vessels, heavy machinery) often have long service lives, and their gaskets may become obsolete. Custom solutions keep these vital assets operational.

-

· Specialty Vehicles and Equipment: From custom hot rods to unique agricultural machinery or military vehicles, any non-standard application requires tailored sealing solutions.

-

· Prototype and R&D Development: When an engineer is designing a new engine or a modified component, custom gaskets are essential for testing and refining the design without the prohibitive cost or lead time of custom tooling for mass production.

-

· Engine Swaps/Conversions: Installing an engine into a chassis it wasn't originally designed for often requires custom adaptations, including bespoke gaskets for intake, exhaust, or cooling systems.

The Customization Process: A Collaborative Journey

Engaging with a specialized custom gasket provider typically involves a structured, collaborative process:

-

1. Consultation and Requirements Gathering: This initial phase is critical. You provide detailed information about your application: engine type, operating conditions (temperatures, pressures), fluids involved, existing part details (if any), desired lifespan, and specific challenges.

-

2. Engineering and Design: The gasket manufacturer's engineering team analyzes your requirements. They may request drawings, digital files (CAD), or even the original mating components. They then propose material options and design iterations, leveraging their expertise in sealing science.

-

3. Prototyping: A prototype is often created, especially for complex or critical applications. This allows for physical fitment checks and initial performance validation.

-

4. Testing and Validation: Depending on the application, prototypes might undergo rigorous testing (e.g., pressure cycling, thermal cycling, leak detection) to confirm performance before full production.

-

5. Production: Once the design is finalized and validated, the custom gaskets are manufactured using the chosen precision cutting or molding techniques.

-

6. Quality Control: Each batch undergoes stringent quality checks to ensure dimensional accuracy, material integrity, and adherence to specifications.

-

7. Support: A reliable custom gasket provider offers ongoing support, troubleshooting, and advice for installation and optimal performance.

Benefits of Partnering for Custom Solutions

Choosing a specialist in customized gasket solutions offers tangible advantages:

-

· Access to Expertise: You gain access to engineers with deep knowledge of materials science, sealing mechanics, and manufacturing processes, guiding you to the optimal solution.

-

· Problem Solving: Custom solutions directly address unique challenges that standard parts cannot, providing precise fixes for difficult leaks or performance bottlenecks.

-

· Performance Gains: Optimized gaskets can enhance engine efficiency, maintain stable compression, and ensure reliable fluid containment, directly contributing to superior performance.

-

· Enhanced Reliability and Longevity: A gasket perfectly suited to its application will last longer and perform more consistently, reducing downtime and costly repairs.

-

· Cost-Effectiveness in the Long Run: While the initial cost of a custom gasket might be higher than a generic one, it prevents repeated failures, expensive labor, and potential damage to major engine components, leading to significant overall savings.

-

· Innovation and Development: Custom gasket capabilities support cutting-edge engine design and modifications, pushing the boundaries of automotive performance.

Future Trends in Gasket Technology and Customization

The field of gasket technology is continuously evolving, driven by demand for higher efficiency, lower emissions, and greater durability. Future trends in customization will likely include:

-

· Smart Gaskets: Incorporating sensors (e.g., for temperature, pressure, or even micro-leaks) directly into the gasket material to provide real-time diagnostic data.

-

· Additive Manufacturing (3D Printing): While not yet widespread for load-bearing gaskets, advancements in material science for 3D printing could enable on-demand fabrication of complex gasket geometries with tailored properties.

-

· Even More Advanced Materials: Development of new polymers, composites, and metallic alloys with enhanced thermal, chemical, and mechanical properties to withstand increasingly extreme engine environments.

-

· Enhanced Surface Engineering: More sophisticated coatings and surface treatments that improve sealing against challenging mating surfaces or provide self-healing properties.

-

· Digital Twins and Predictive Analytics: Using highly detailed digital models of gasket performance to predict lifespan and optimize maintenance schedules for custom solutions.

Conclusion: The Unseen Value of Precision in Sealing

The engine gasket, often an afterthought, is in fact a highly engineered component crucial to the performance, efficiency, and longevity of any engine. While standard gaskets meet most needs, the demands of unique applications, extreme performance, or legacy machinery necessitate a tailored approach.

Customized engine gasket solutions represent the pinnacle of sealing technology, offering comprehensive optimization from the selection of the most suitable materials to the meticulous design and manufacturing of precise dimensions. By collaborating with experts who understand the nuances of material science, engineering principles, and manufacturing precision, you can unlock unparalleled reliability and performance.

At WTA GASKET, we pride ourselves on being at the forefront of this specialized field. Our expertise in designing and producing customized engine gaskets – whether for specific material requirements, non-standard dimensions, or unique sealing challenges – ensures that your engine performs at its best, whatever its purpose. Investing in a tailored sealing solution isn't just about preventing leaks; it's about optimizing an entire system, ensuring peak efficiency, maximizing lifespan, and providing the ultimate peace of mind.

Frequently Asked Questions

Welcome to the SOYI FAQ, where we address common questions about our automotive engine gasket repair kits and sealing components.

Whether you need information on product specifications, ordering processes, or troubleshooting tips, our comprehensive FAQ section provides clear and helpful answers.

OEM&ODM

What is your terms of delivery?

EXW, FOB

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

How about your delivery time?

Generally, it will take 5 to 7 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

What is your terms of packing?

Generally, we pack our goods in WTA and SOYI packing. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Get a free quote

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

Your inquiries, ideas, and collaboration opportunities are just a click away. Let's start the conversation.

Scan QR Code

Scan QR Code

Tik Tok

YouTube

Facebook

LinkedIn

Scan QR Code

Whatsapp: +8618922275934

Whatsapp: +8618922276204

Whatsapp: +8618922271543