OEM/ODM head gasket Manufacturers and Suppliers

- Understanding the Head Gasket's Importance in Engine Sealing

- Benefits of OEM/ODM Head Gasket Solutions

- WTA Gasket: A Leading Name Among OEM/ODM Head Gasket Manufacturers

- Material Selection: Specialized Head Gaskets for Diverse Applications

- Why Choose WTA Gasket as Your Head Gasket Supplier?

- Key Considerations for Sourcing OEM/ODM Head Gasket Manufacturers

- OEM vs. ODM Head Gasket Manufacturing: Understanding the Difference

- Serving a Wide Range of Automotive Brands

- The Advantages of Partnering with an Expert Head Gasket Manufacturer

- Applications Beyond Standard Automotive Engines

- FAQs:

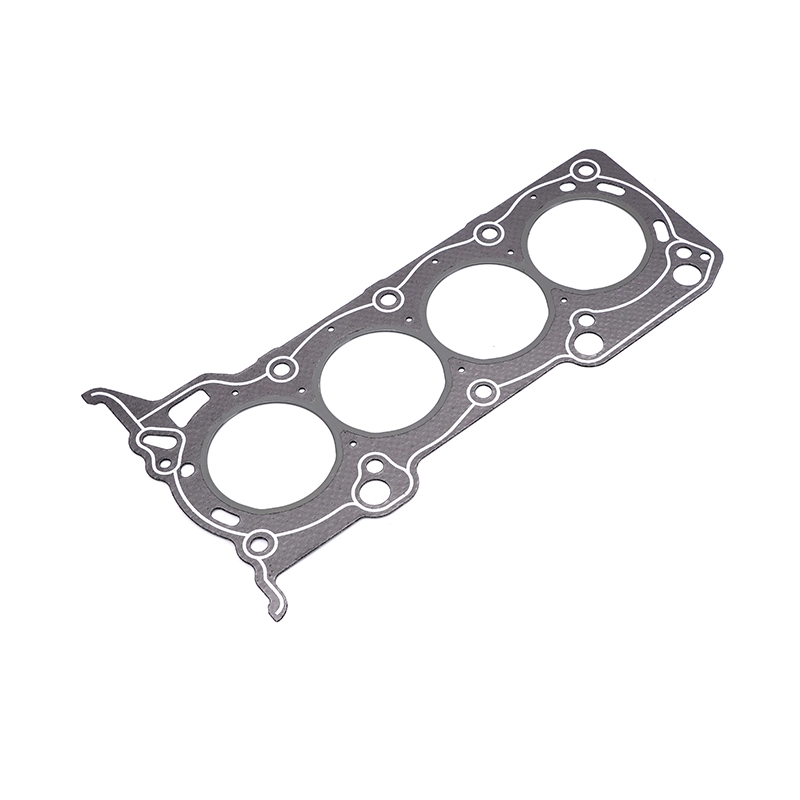

The Vital Role of the Head Gasket

In automotive engineering, the head gasket is a critical component of engine performance and reliability. Positioned between the engine block and cylinder head, a head gasket ensures a leak-proof seal, maintaining optimal compression while preventing coolant or engine oil from leaking into the cylinders. As globalization accelerates automotive manufacturing, sourcing reliable OEM/ODM head gasket manufacturers and suppliers has become essential for carmakers and aftermarket brands. we spotlight WTA Gasket—a world-class provider of automotive engine sealing solutions specializing in OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for head gaskets and more.

Understanding the Head Gasket's Importance in Engine Sealing

A head gasket’s function transcends simple separation. It must withstand high-pressure environments, varying temperatures, and diverse engine loads, ensuring the engine runs smoothly without leaks. Effective head gaskets help maintain compression necessary for engine power, prevent fluids from mixing, and contribute to overall vehicle longevity. Any failure in the head gasket can lead to catastrophic engine damage, emphasizing the importance of precision manufacturing and strict quality control in head gasket production.

Benefits of OEM/ODM Head Gasket Solutions

Customization for Specific Automotive Needs

OEM/ODM head gasket manufacturers offer unparalleled customization to meet exact engine requirements or to develop new designs for emerging engine models. Whether you are developing unique engine platforms or need gaskets for established brands such as Toyota, Nissan, Mitsubishi, or BMW, an experienced ODM/OEM supplier like WTA Gasket delivers tailor-made solutions, optimizing fit and function.

Consistent Quality Assurance

Working with certified head gasket manufacturers guarantees consistent quality, thanks to advanced testing equipment, material traceability, and robust manufacturing protocols. Reputable companies prioritize durability, ensuring that each batch of overhaul repair kits or valve cover gaskets meets industry standards.

Streamlined Supply Chain

Trusted suppliers simplify the sourcing process, enabling OEM partners and aftermarket retailers to shorten lead times and enhance inventory management. A reliable manufacturer can scale up with your business, handling everything from product design to mass production and packaging.

WTA Gasket: A Leading Name Among OEM/ODM Head Gasket Manufacturers

Company Background and Expertise

Founded in 2012, WTA Gasket specializes in automotive engine sealing solutions, focusing on the production of cylinder head gaskets, overhaul repair kits, precision components, and more. With customer satisfaction at its core, WTA has become a trusted partner for brands worldwide seeking the best cost performance and exceeding industry expectations. The company’s expertise spans an extensive range of gaskets, including compound graphite, non-compound graphite, asbestos, and multilayer metal variants.

Comprehensive Product Portfolio

WTA Gasket produces a vast array of components under its OEM/ODM model:

- Cylinder head gaskets

- Overhaul repair kits

- Valve cover gaskets

- Oil pan gaskets

- Intake/exhaust manifold gaskets

- Custom engine sealing for leading automotive makes (Toyota, Nissan, Mitsubishi, Honda, Mazda, Isuzu, Kia, Daewoo, Volkswagen, Cetrion, Ford, GM-Buick, Chery, Hino, BMW, Chevrolet, etc.)

This broad selection enables WTA to serve global automotive and industrial clients, supporting both well-known and emerging vehicle brands.

Advanced Design, Testing, and Manufacturing

WTA Gasket combines cutting-edge technology with expert craftsmanship. The design team can develop or reverse-engineer all types of gasket structures, using state-of-the-art materials that ensure maximum durability and sealing performance in harsh operating conditions. Each gasket undergoes rigorous testing, simulating real-world conditions to verify resistance to heat, pressure, and chemical exposure.

Material Selection: Specialized Head Gaskets for Diverse Applications

The right material determines the effectiveness and lifespan of a head gasket. WTA Gasket’s expertise covers a comprehensive range of options:

Compound Graphite Gaskets

Known for their excellent thermal conductivity and adaptability, compound graphite gaskets provide superior sealing under fluctuating temperatures. They are ideal for high-performance and turbocharged engines.

Multilayer Metal (MLS) Gaskets

MLS head gaskets offer unbeatable strength and resilience, handling extreme pressure and heat—a common feature in modern performance engines and trucks.

Asbestos and Non-Compound Variants

For older models or special-purpose engines, WTA also manufactures asbestos and non-compound graphite gaskets, ensuring compatibility and longevity.

Why Choose WTA Gasket as Your Head Gasket Supplier?

Industry Certifications and Global Reach

WTA adheres to international standards, implementing ISO-certified quality management systems. With an established presence across global markets, buyers can expect timely deliveries, clear communication, and comprehensive after-sales support.

Custom Design and Rapid Prototyping

Through its advanced R&D capabilities, WTA Gasket swiftly transforms customer requirements into manufacturable solutions. Whether you need a single prototype for testing or a large batch for production, WTA offers flexibility and technical assistance at every stage.

Competitive Pricing and Cost Performance

WTA Gasket pursues optimal cost performance by optimizing manufacturing processes and material sourcing. Clients benefit from attractive pricing without compromising product quality or reliability.

Key Considerations for Sourcing OEM/ODM Head Gasket Manufacturers

Technical Support and Consultation

Look for head gasket suppliers that provide technical consultation, assisting with material selection, design tweaks, and compatibility checks. Expert input during early development stages can reduce problems during production and installation.

Supply Stability and Scalability

A strong manufacturing partner offers consistent, scalable capacity, meeting the needs of both small runs and high-volume contracts. WTA’s automated facilities and experienced workforce ensure uninterrupted supply and on-time delivery.

Warranties and After-Sales Service

An OEM/ODM head gasket supplier should stand by its products. WTA offers comprehensive warranties, supporting clients with technical documentation, installation tips, and troubleshooting guidance.

OEM vs. ODM Head Gasket Manufacturing: Understanding the Difference

OEM Head Gasket Manufacturing

OEM services focus on producing head gaskets according to the client's designs and specifications. This option is ideal for automotive brands and parts distributors who have unique engineering requirements or are replacing existing components.

ODM Head Gasket Solutions

ODM manufacturing involves developing new designs based on general specifications, often leveraging the manufacturer’s R&D and innovation capacity. With ODM, vehicle manufacturers and aftermarket brands can introduce proprietary gaskets, gaining a competitive edge through customization.

Serving a Wide Range of Automotive Brands

WTA Gasket’s international client roster spans Asian, American, and European automotive leaders. The factory supports manufacturers like Toyota, Nissan, Honda, Mazda, Volkswagen, Ford, GM-Buick, BMW, Chevrolet, and local brands such as Chery and Hino. WTA’s adaptability ensures clients receive precisely engineered engine sealing products regardless of make or model.

The Advantages of Partnering with an Expert Head Gasket Manufacturer

- Enhanced product reliability and customer confidence

- Access to the latest material and production innovations

- Custom-tailored solutions for diverse engine platforms

- Streamlined purchasing and logistics

- Global support and multilingual service

Applications Beyond Standard Automotive Engines

WTA Gasket’s engineering expertise goes beyond cars and trucks, extending into agricultural machinery, generators, marine engines, and industrial power units. This flexibility makes the company an ideal partner for anyone seeking specialized engine sealing solutions.

FAQs:

What is a head gasket and why is it important?

A head gasket is a sealing component between the engine block and cylinder head, preventing leaks and maintaining compression, essential for engine performance and reliability.

What materials are used in high-quality head gaskets?

WTA produces head gaskets from compound graphite, non-compound graphite, asbestos, and multilayer metals (MLS), each suited to different engine types and applications.

What is the difference between OEM and ODM head gasket manufacturing?

OEM manufacturing follows the buyer’s precise specifications, while ODM involves creating new designs based on general requirements or trends set by the manufacturer.

Which brands can WTA provide head gaskets for?

WTA manufactures engine gaskets for Toyota, Nissan, Mitsubishi, Honda, Mazda, Volkswagen, Ford, BMW, GM-Buick, Chevrolet, Hino, Daewoo, Kia, Chery, Isuzu, and many more.

Does WTA support custom design and rapid prototyping?

Yes, WTA offers custom design, engineering consultation, and rapid prototyping for all head gasket projects.

How can I request a quotation or more info?

Contact WTA’s sales team via the company website or by email/phone. Our team will respond promptly with detailed product info and a competitive quotation.

Partnering with an industry leader like WTA Gasket ensures you receive advanced, reliable, and cost-effective OEM/ODM head gasket solutions for all your automotive and industrial needs. For more information, custom quotes, or technical consultation, reach out to WTA Gasket—your trusted head gasket manufacturer and supplier.

Tips for Wholesale Diesel Engine Gaskets

The 10 Key Factors in engine gasket kit That Affect Cost

Top 3rz cylinder gasket Manufacturers and Suppliers

How to Choose Right ford fiesta cylinder head gasket manufacturer and supplier in US?

OEM&ODM

What is your sample policy?

We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

How about your delivery time?

Generally, it will take 5 to 7 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

What is your terms of packing?

Generally, we pack our goods in WTA and SOYI packing. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

Head gasket top gasket for Mitsubishi 4A91 OEM MN195370

WTA Head gasket top gasket for Mitsubishi 4A91 (OEM MN195370) — precision-engineered replacement to restore sealing integrity, prevent leaks and ensure optimal compression. Durable, OEM-equivalent fit for reliable engine performance. Want edits or variants?

High Quality Full Gasket Set 8ASX-10-271 WL Engine Overhaul Gasket Kits for Mazda B-SERIE 2.5

For ISUZU 6BG1 Truck Fit 1986-1992 F-Series FSR 500 FVR 12 JCS 420 1-87810609-0 Engine Head Gasket Kit Full Set 1878106090

Scan QR Code

Scan QR Code

Tik Tok

YouTube

Facebook

LinkedIn

Scan QR Code

Whatsapp: +8618922275934

Whatsapp: +8618922276204

Whatsapp: +8618922271543